LNG FACILITIES

Detection Products for Liquefied Natural Gas Processing & Storage

LNG terminals, liquefaction plants, and regasification sites operate with extremely cold temperatures, high-pressure gas systems, and large inventories of flammable material.

To support safe handling and continuous operation, Omniguard advanced flame and gas detection products engineered for cryogenic and hydrocarbon environments.

Our detectors deliver reliable early warning, enabling controlled shutdown, isolation, and prevention of fire escalation in LNG applications.

3–5 seconds

time in which an unignited vapor cloud can reach dangerous size under calm conditions.

> 40 %

of LNG incidents originate from piping, valves, and transfer operations.

Why LNG environments require specialized detection

LNG facilities present a combination of risks not found in other industrial settings: cryogenic spills, rapid vaporization, dense gas clouds, and ignition potential around pumps and piping.

Operational challenges that increase the need for advanced detection include:

- LNG leaks forming cold vapor clouds that can travel long distances

- Rapid phase transition from liquid to flammable gas

- Ignition sources near pumps, compressors, and vaporizers

- Harsh weather, wind, and sunlight affecting sensor performance

- Outdoor, large-scale layouts requiring robust detection coverage

- Classified hazardous areas (ATEX/IECEx) throughout the facility

Omniguard detection technologies for fuel environments

Omniguard flame and gas detectors are engineered to perform in cryogenic, outdoor, and high-risk hydrocarbon environments, providing fast response to both vapor and flame events.

Our detection products support:

- Fast response time and long detection distance

- Wide viewing angles

- Designed for easy cleaning and maintenance

- All models are available with Aluminum or Stainless-Steel housing

- Worldwide service and support network

Where risks typically arise

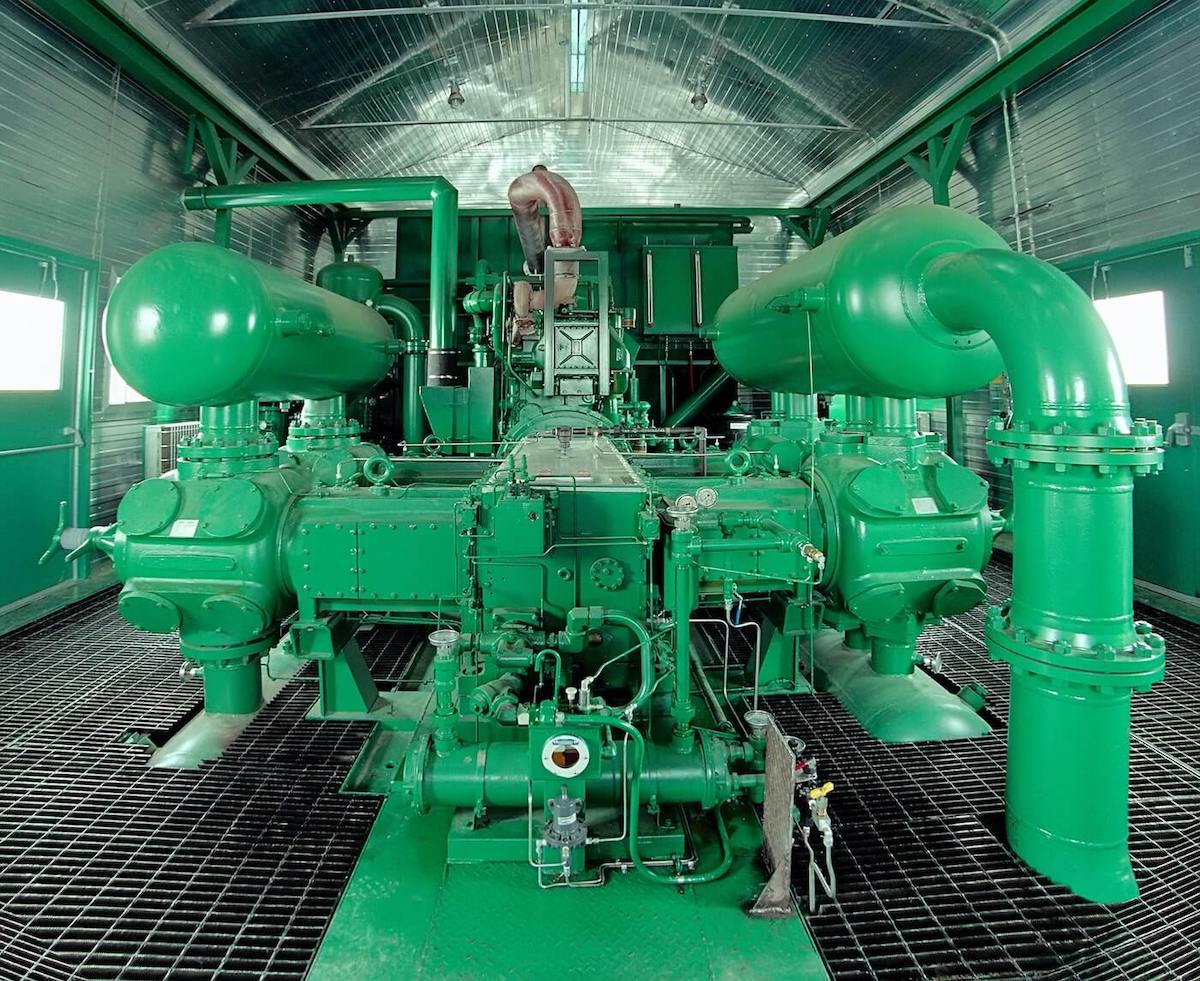

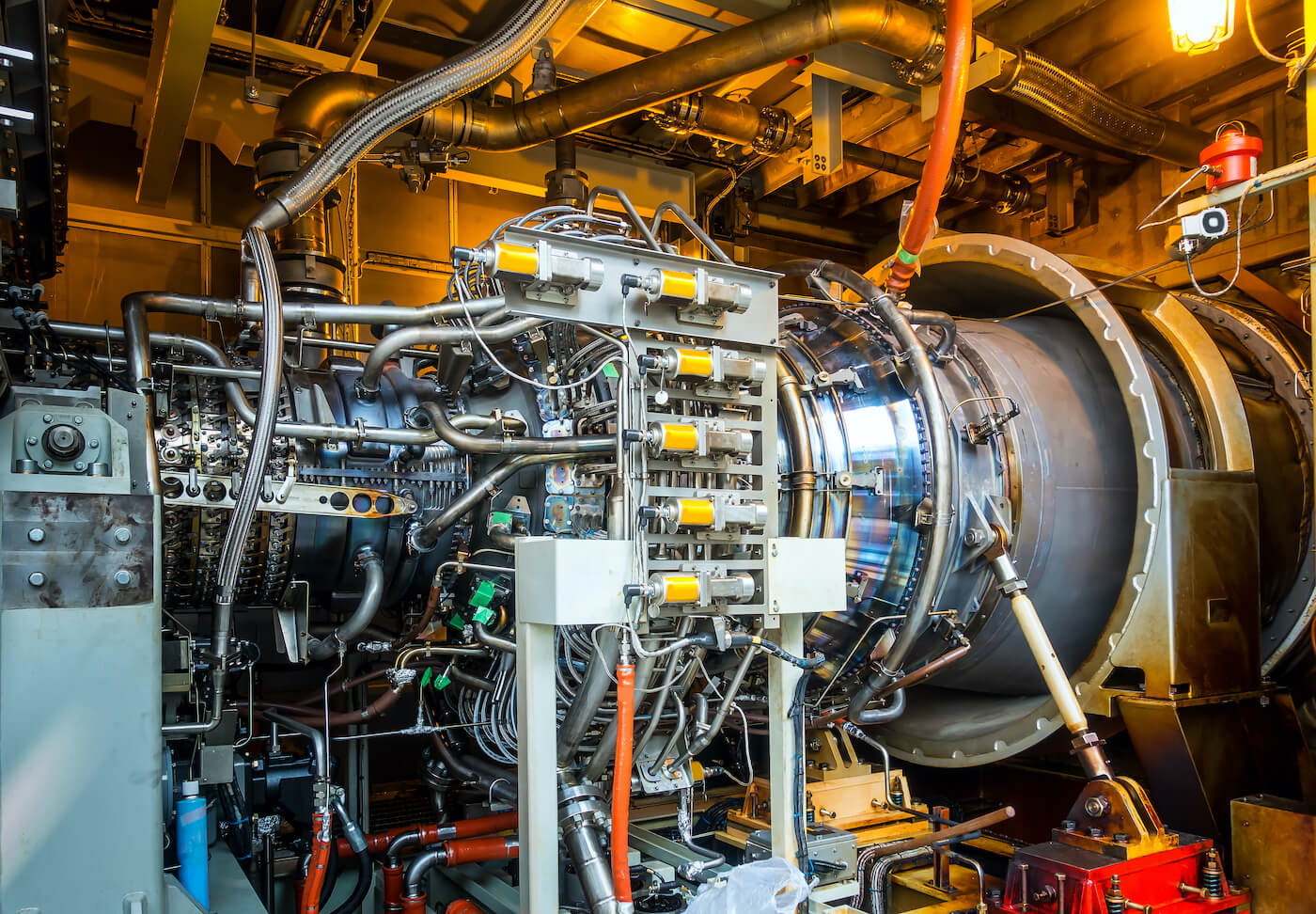

LNG facilities contain several high-risk areas that require particular attention. Transfer equipment — including loading arms, hoses, and pump skids — must be continuously monitored for leaks or mechanical failures. Storage tank domes and valve pits are exposed to cryogenic spills and boil-off gas releases. Liquefaction and regasification units contain rotating machinery, vaporizers, high-pressure piping and instrumentation where ignition sources may be present.

Marine loading areas also introduce additional complexity, as ship movements, weather exposure and dynamic operations increase the need for reliable, fast-responding detection. Across these environments, the potential for ignition near compressors, electrical equipment or hot surfaces reinforces the importance of early warning systems.

Additional Resources

Articles

Trusted Half a Century and How OmniGuard Leads Flame and Gas Detection Innovation >

From Hangars to Hydrogen and OmniGuard’s Expertise in High Stakes Environments >

Meet the Models and Choosing Between OmniGuard’s 660 760 and 860 Flame Detectors >

Precision Tested and How OmniGuard’s 540 545 Test Sources Ensure Detector Reliability >