LGP FACILITIES

Fire & Gas Detection for Pressurized LPG Handling and Storage

Liquefied Petroleum Gas (LPG) facilities — whether used for bulk storage, cylinder filling, transport depots, or industrial supply — operate with highly flammable gas under pressure. LPG’s behaviour, including its ability to form dense vapor clouds that can accumulate at ground level, creates a fire and explosion profile that requires fast, reliable detection.

Omniguard provides high-performance flame and gas detection products engineered for LPG operations, supporting safe handling, leak prevention, and early intervention when incidents occur.

Our detectors help operators, integrators and engineering firms build robust safety strategies for LPG production, distribution, and end-use applications.

Up to 65 %

reduction in fire damage when leaks or flames are detected early.

>60 %

of LPG-related incidents start with small leaks during transfer or cylinder handling.

The characteristics of LPG that elevate fire risk

LPG behaves differently from many other fuels: it expands rapidly when released, forms dense vapors that settle near the ground, and ignites easily from heat, static, or electrical sparks. Because of this, facilities require detection systems that are highly responsive, stable in outdoor conditions, and capable of identifying both flames and low-concentration gas clouds.

Even routine operations, such as cylinder filling or truck loading, involve continuous handling of pressurized liquid and vapor — increasing the chance of minor leaks that can accumulate unnoticed without proper detection.

Detection technology that suits LPG environments

Omniguard detectors are designed to withstand the operational realities of LPG sites — outdoor exposure, reflective metal surfaces, high vibration, and constant activity. Our flame detectors respond quickly to ignition events, even in bright sunlight, and our gas detectors identify LPG vapor before concentrations reach dangerous levels.

Our detection products support:

- Fast response time and long detection distance

- Wide viewing angles

- Designed for easy cleaning and maintenance

- All models are available with Aluminum or Stainless-Steel housing

- Worldwide service and support network

Where incidents typically begin in LPG operations

In many LPG facilities, elevated risk comes from equipment that experiences frequent mechanical stress: loading arms, transfer hoses, welded joints, and tank valves. Small seal or gasket failures can produce vapor clouds that spread along the ground, often accumulating around pits or structures.

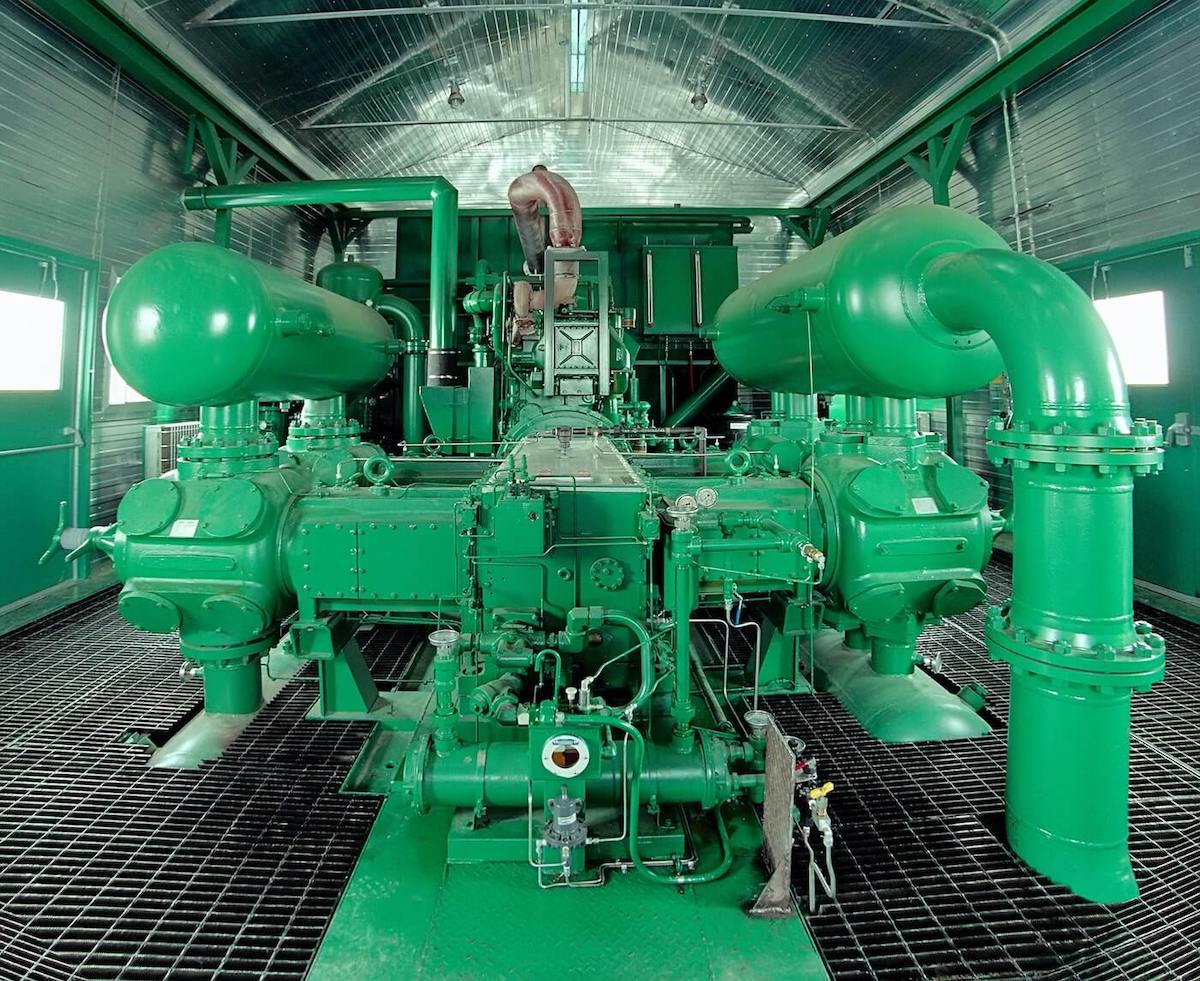

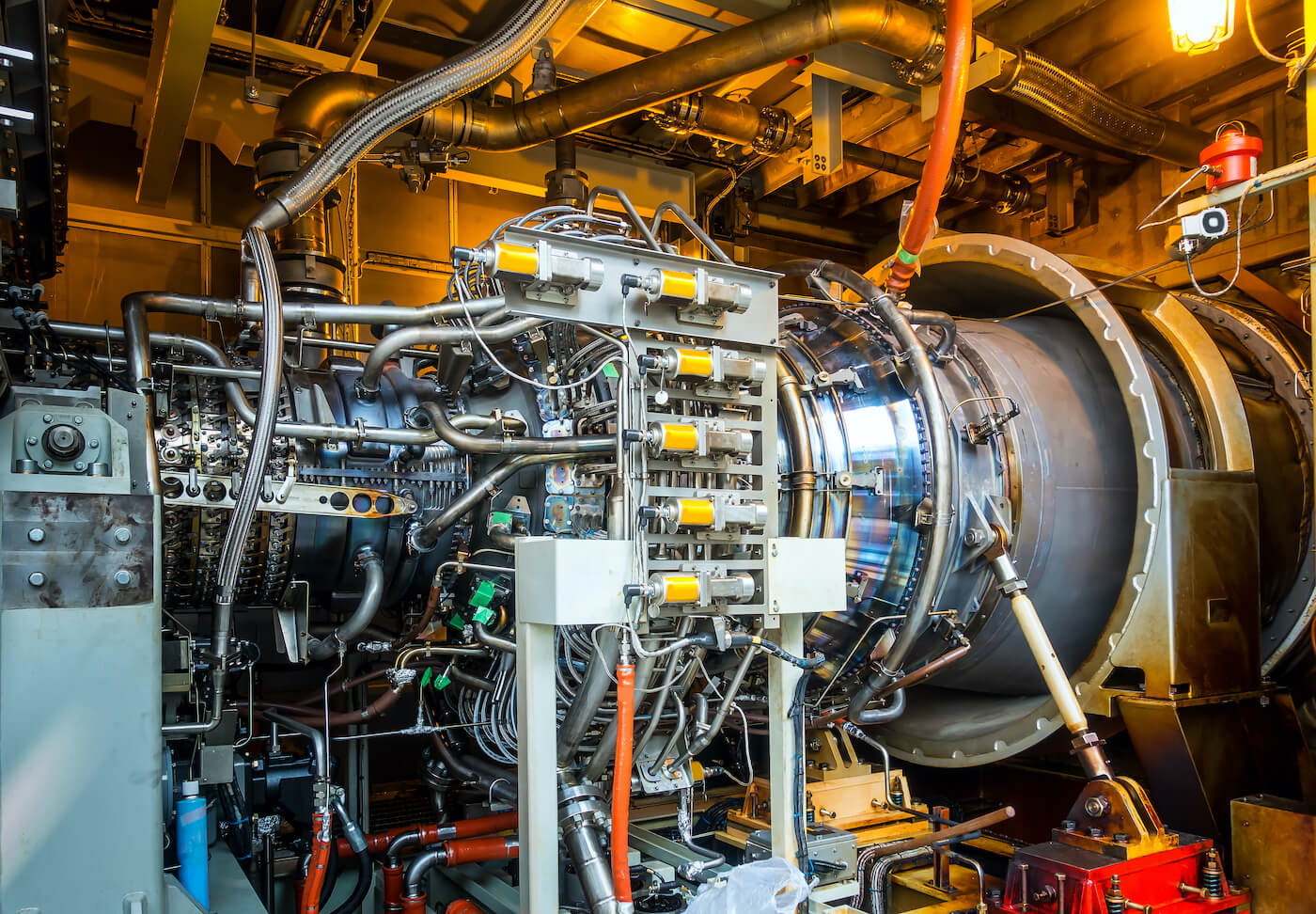

Cylinder filling areas represent another high-exposure zone, as repeated connection and disconnection cycles increase the potential for small releases. Pump rooms, compressor skids, and pressure-reducing stations introduce ignition sources that, when combined with leaks, can lead to rapid fire development.

Performance expectations for LPG detection systems

A well-designed detection strategy for LPG must do more than simply alarm when fuel is present. It should provide early insight into developing leaks, integrate with emergency shutdown equipment, and allow operators to isolate pumps, valves, or filling lines.

Detection systems must also be built to handle weather exposure, dust, and thermal shifts, while maintaining accuracy in areas where vapor may pool or move unpredictably. Compliance with hazardous-area requirements is essential, as many LPG sites involve classified zones.

Omniguard products meet these standards by combining fast reaction times with robust environmental resistance.

Additional Resources

Articles

Trusted Half a Century and How OmniGuard Leads Flame and Gas Detection Innovation >

From Hangars to Hydrogen and OmniGuard’s Expertise in High Stakes Environments >

Meet the Models and Choosing Between OmniGuard’s 660 760 and 860 Flame Detectors >

Precision Tested and How OmniGuard’s 540 545 Test Sources Ensure Detector Reliability >