PETROCHEMICAL PLANTS

Precision Fire & Gas Detection for High-Hazard Hydrocarbon Processing

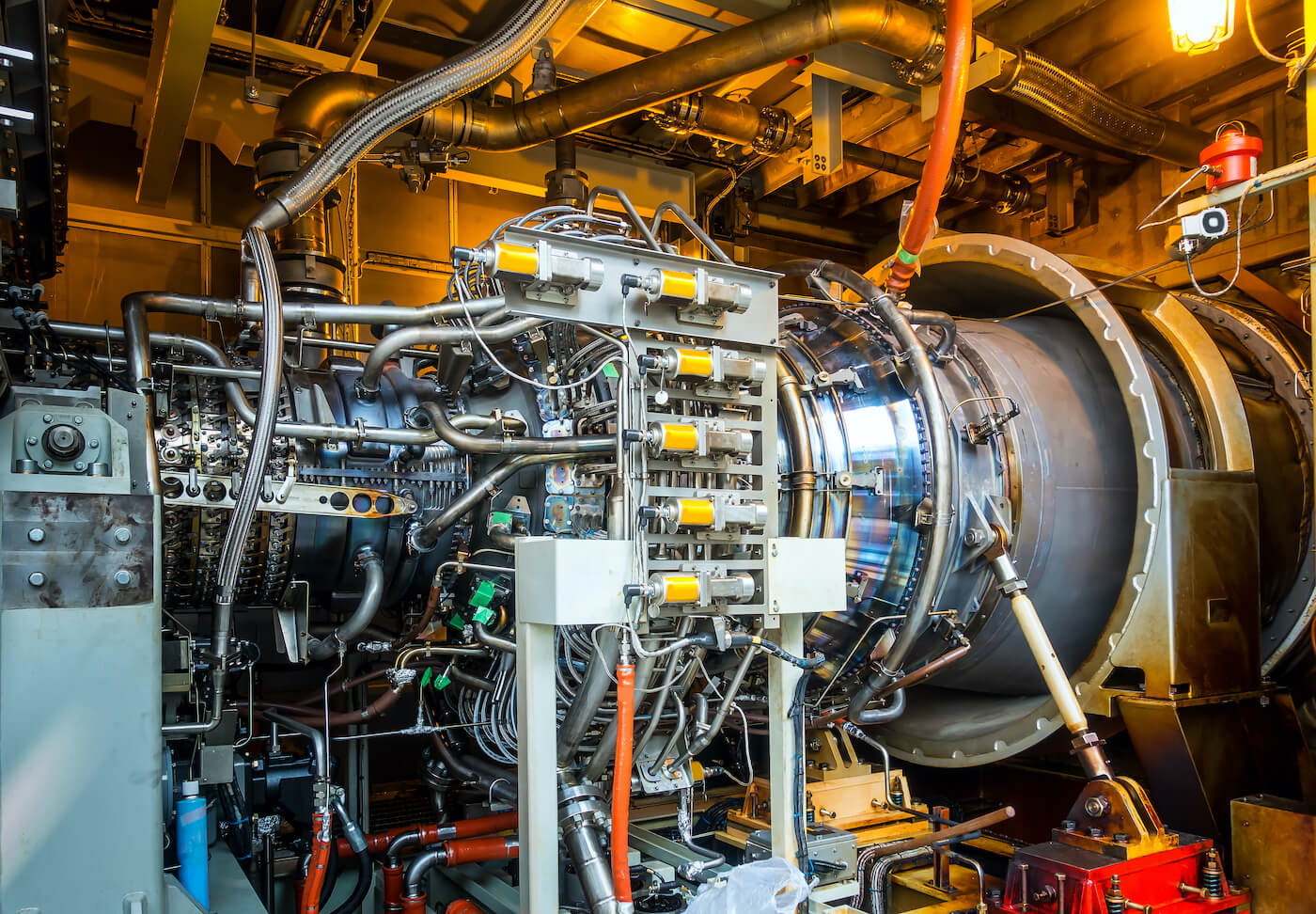

Petrochemical complexes involve some of the most demanding and high-risk industrial processes anywhere. Cracking units, reformers, distillation towers, compressor stations, and tank farms all operate with flammable hydrocarbons under heat and pressure.

$1+ million

Typical economic impact of downtime caused by a fire in a petrochemical production unit.

30–40%

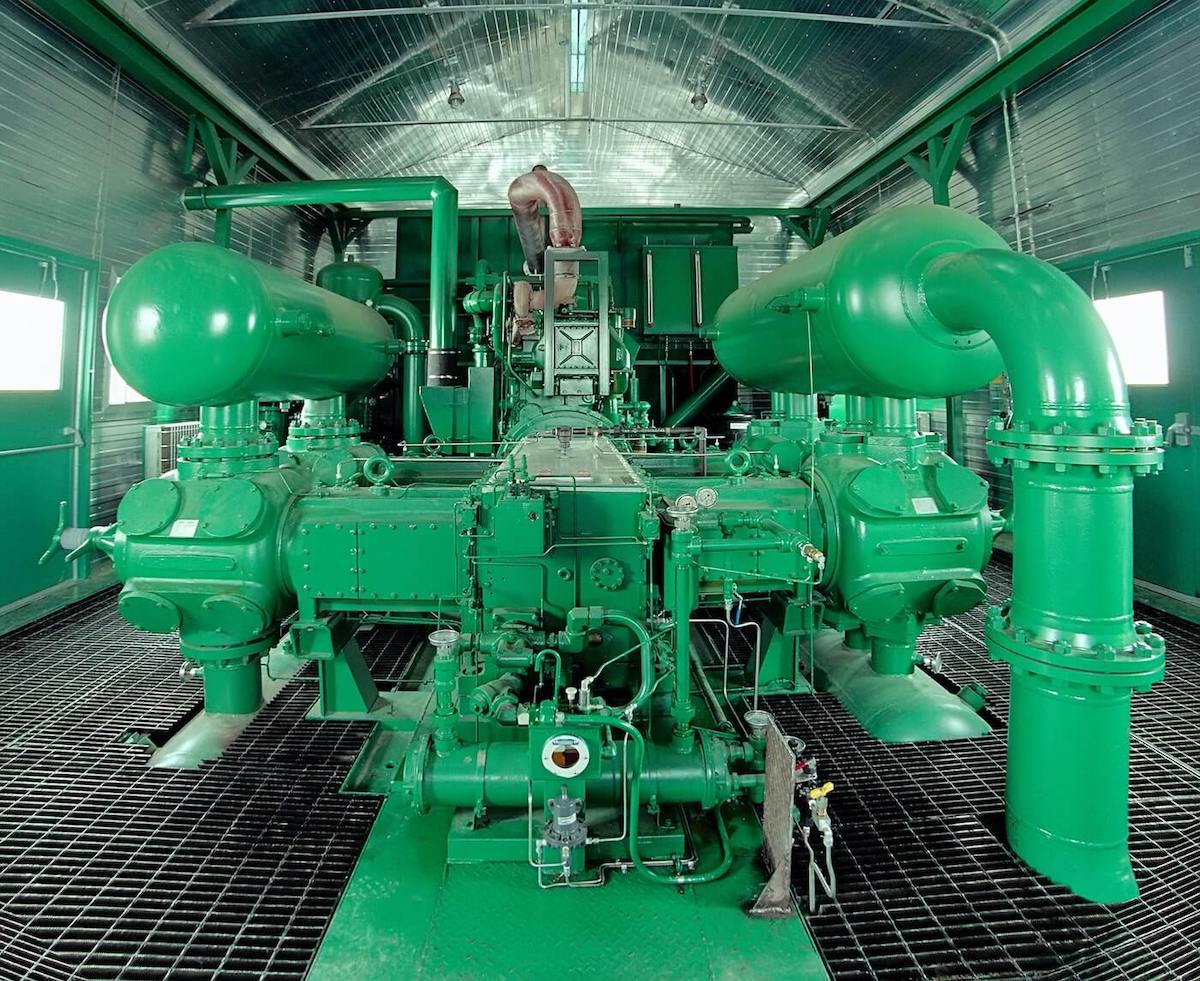

of petrochemical fires originate at pumps or compressors.

A landscape of high energy, heat, and volatile materials

Hydrocarbon processing relies on intense temperatures, catalytic reactions, and continuous vapor movement. A minor equipment fault — a leaking pump seal, overheated motor, worn flange, or compressor vibration — can release vapor that ignites in moments.

Because petrochemical plants run 24/7 with complex interconnected systems, early detection is critical to prevent fire escalation and protect critical units from shutdown.

Detection products engineered for petrochemical realities

Omniguard flame and gas detectors are built to withstand extreme temperatures, bright sunlight, mechanical vibration, corrosive atmospheres, and the dense steel structures common in petrochemical plants.

Flame detectors deliver fast, accurate recognition of hydrocarbon fires even in complex lighting or reflective environments. Gas detectors monitor for leaks around pumps, reformers, reactors, storage tanks, and transfer systems — enabling early action before conditions escalate.

Our detection products support:

- Fast response time and long detection distance

- Wide viewing angles

- Designed for easy cleaning and maintenance

- All models are available with Aluminum or Stainless-Steel housing

- Worldwide service and support network

How hazards typically emerge in petrochemical operations

Many incidents can be traced back to small, early-stage warning signs. Vapors escaping from worn gaskets, compressor housings, or valve manifolds may go unnoticed until they reach an ignition source. Heat-exchangers and furnace areas can experience thermal anomalies. Storage tanks and loading racks contain large volumes of volatile liquids with their own ignition potential.

Chemical reactions inside process units further complicate risk: pressure deviations, incomplete combustion, or upset conditions can create flammable atmospheres rapidly.

These subtle beginnings require detection products that respond immediately and remain stable despite harsh outdoor and process conditions.

Supporting diverse units across a petrochemical complex

Petrochemical sites are made up of many specialized areas — cracking furnaces, polymerization plants, tank farms, pump stations, blending lines, and marine or rail loading terminals.

Omniguard detectors integrate easily across these varied environments, offering consistent, dependable detection whether installed on new projects, modern upgrades, or brownfield expansions.

Additional Resources

Articles

Trusted Half a Century and How OmniGuard Leads Flame and Gas Detection Innovation >

From Hangars to Hydrogen and OmniGuard’s Expertise in High Stakes Environments >

Meet the Models and Choosing Between OmniGuard’s 660 760 and 860 Flame Detectors >

Precision Tested and How OmniGuard’s 540 545 Test Sources Ensure Detector Reliability >