REFINERIES

Advanced Flame & Gas Detection for Oil Refining, Process Units & Hydrocarbon Handling

Oil refineries are among the most complex and high-risk industrial facilities in operation. Crude oil entering a refinery passes through furnaces, distillation towers, reactors, exchangers, compressors, hydroprocessing units, and storage areas — all of which involve flammable hydrocarbons, elevated temperatures, and pressurized systems.

Omniguard by Firefly provides high-performance flame and gas detection products designed specifically for refining environments where rapid ignition, vapor release, or equipment overheating can escalate into significant incidents if not detected early.

Our detection solutions help operators improve refinery safety, reduce downtime, and maintain stable production across all key refining units.

$1–10 million

typical economic impact of a single fire-related shutdown of a major process unit.

>50%

of refinery incidents occur during startup, shutdown, or maintenance activities.

Refining operations: where heat, chemistry & pressure create constant fire risk

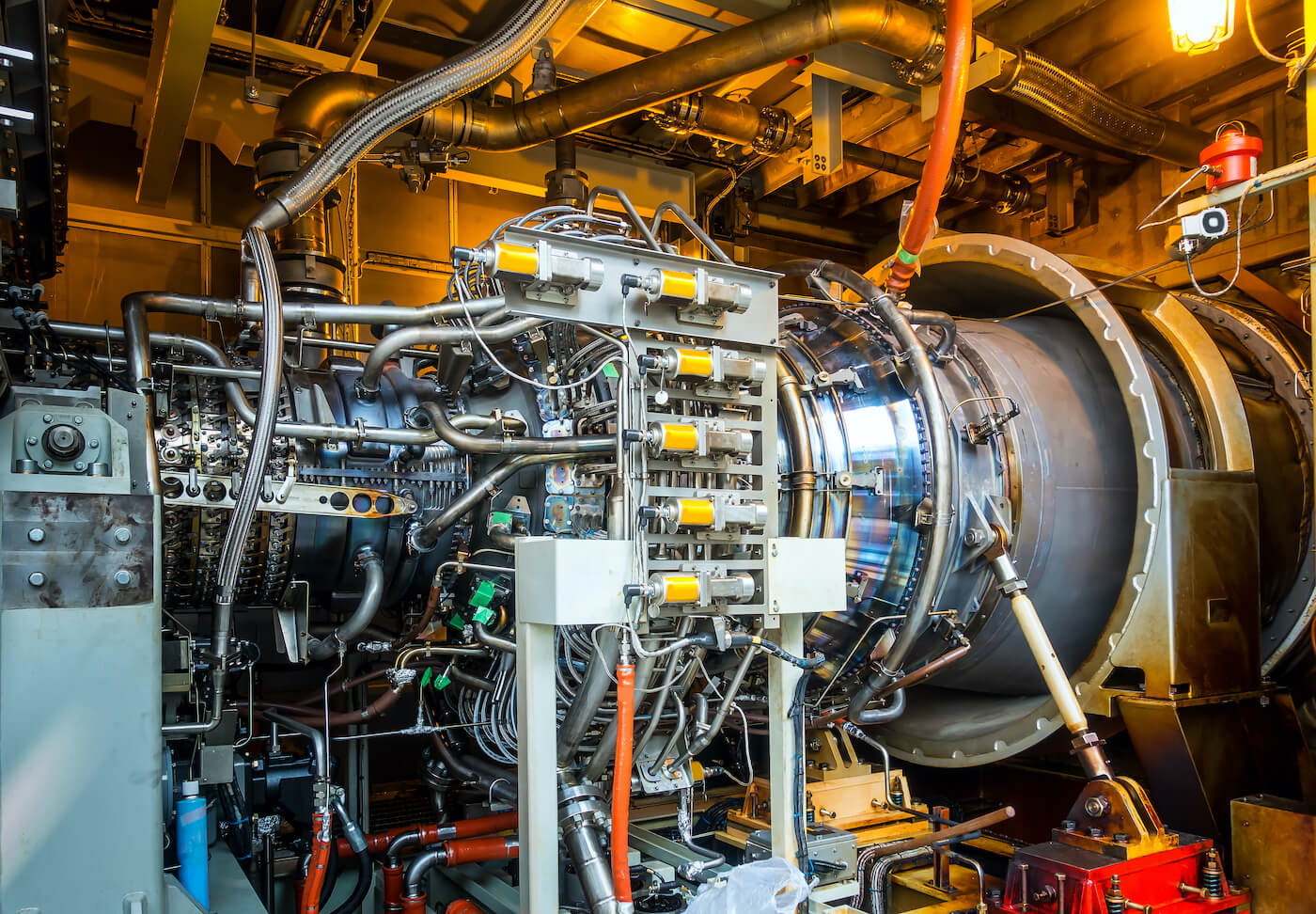

Modern oil refineries rely on high-temperature processes, catalytic reactions, hydrogen-rich environments, and continuous throughput. These conditions create an atmosphere where even a minor leak — a worn pump seal, a pinhole in a heat exchanger, or a failing flange — can release explosive hydrocarbon vapors.

High-temperature furnace operations, catalytic cracking units, and hydrotreaters introduce further ignition potential. And because refineries work 24/7 with integrated process units, an undetected fire event can disrupt multiple parts of the plant simultaneously.

Early flame and gas detection becomes a critical line of defense in ensuring operational safety.

Omniguard detection are engineered for refining conditions

Omniguard detection products are engineered for locations where maintenance intervals may be long and environmental conditions harsh.

Refineries demand detection equipment that performs under extreme conditions: high temperatures, corrosive atmospheres, bright sunlight, steam plumes, vibration, and long sightlines across open process areas.

Omniguard flame detectors offer rapid, reliable hydrocarbon flame recognition, even in environments with glare, flare stacks, or reflective metal. Our gas detectors identify explosive atmospheres forming around pumps, exchangers, valve manifolds, and storage tanks — enabling early intervention before escalation.

Our detection products support:

- Fast response time and long detection distance

- Wide viewing angles

- Designed for easy cleaning and maintenance

- All models are available with Aluminum or Stainless-Steel housing

- Worldwide service and support network

Typical ignition sources in refinery environments

Many refinery fires begin in areas where mechanical stress, thermal load, and hydrocarbon flow intersect:

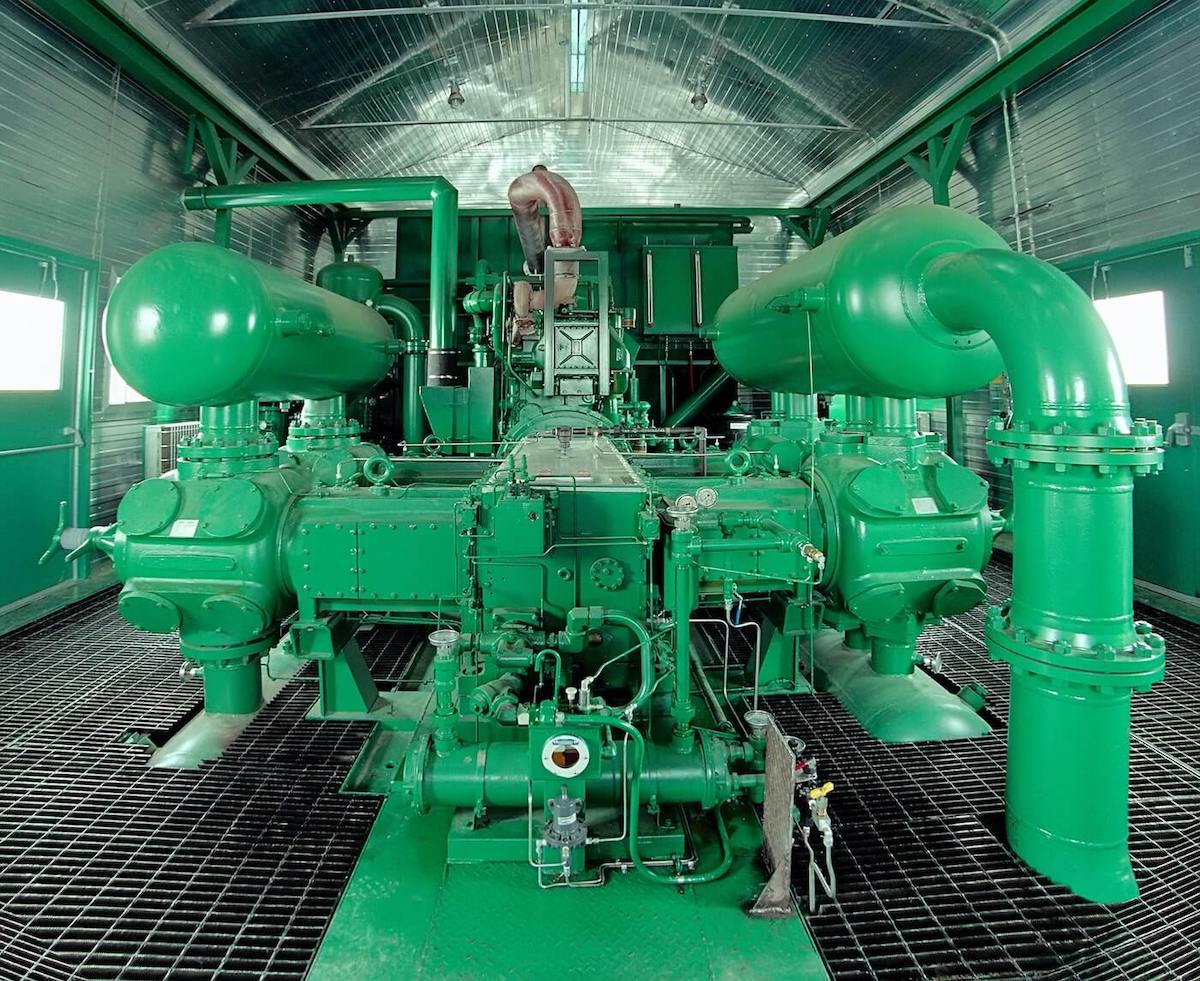

- Pump and compressor leaks

- Furnace and heater zones

- Valve manifolds and pipe racks

- Heat exchangers and reactors

- Hydrocracker and reformer units

- Tank farms and loading racks

In highly congested process areas, a small flame or gas cloud can spread rapidly if not detected immediately.

Contact us

If you’re looking for reliable flame or gas detection products for refinery applications, we’re here to support your safety and operational goals.

Contact us and we’ll help you select the best detectors for your refining environment.

Additional Resources

Articles

Trusted Half a Century and How OmniGuard Leads Flame and Gas Detection Innovation >

From Hangars to Hydrogen and OmniGuard’s Expertise in High Stakes Environments >

Meet the Models and Choosing Between OmniGuard’s 660 760 and 860 Flame Detectors >

Precision Tested and How OmniGuard’s 540 545 Test Sources Ensure Detector Reliability >