TURBINE ENCLOSURE

Flame & Gas Detection for Enclosed Gas and Steam Turbine Installations

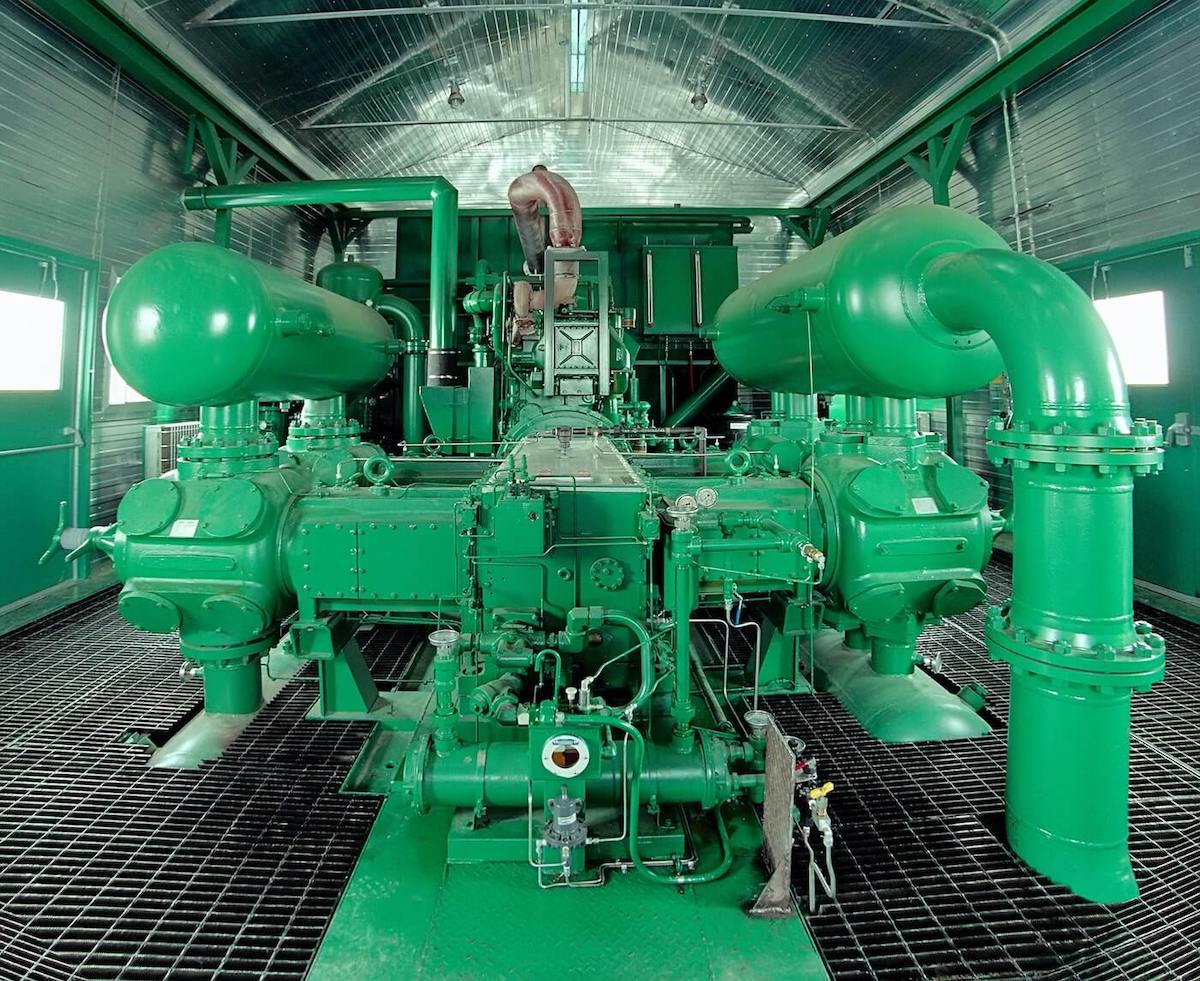

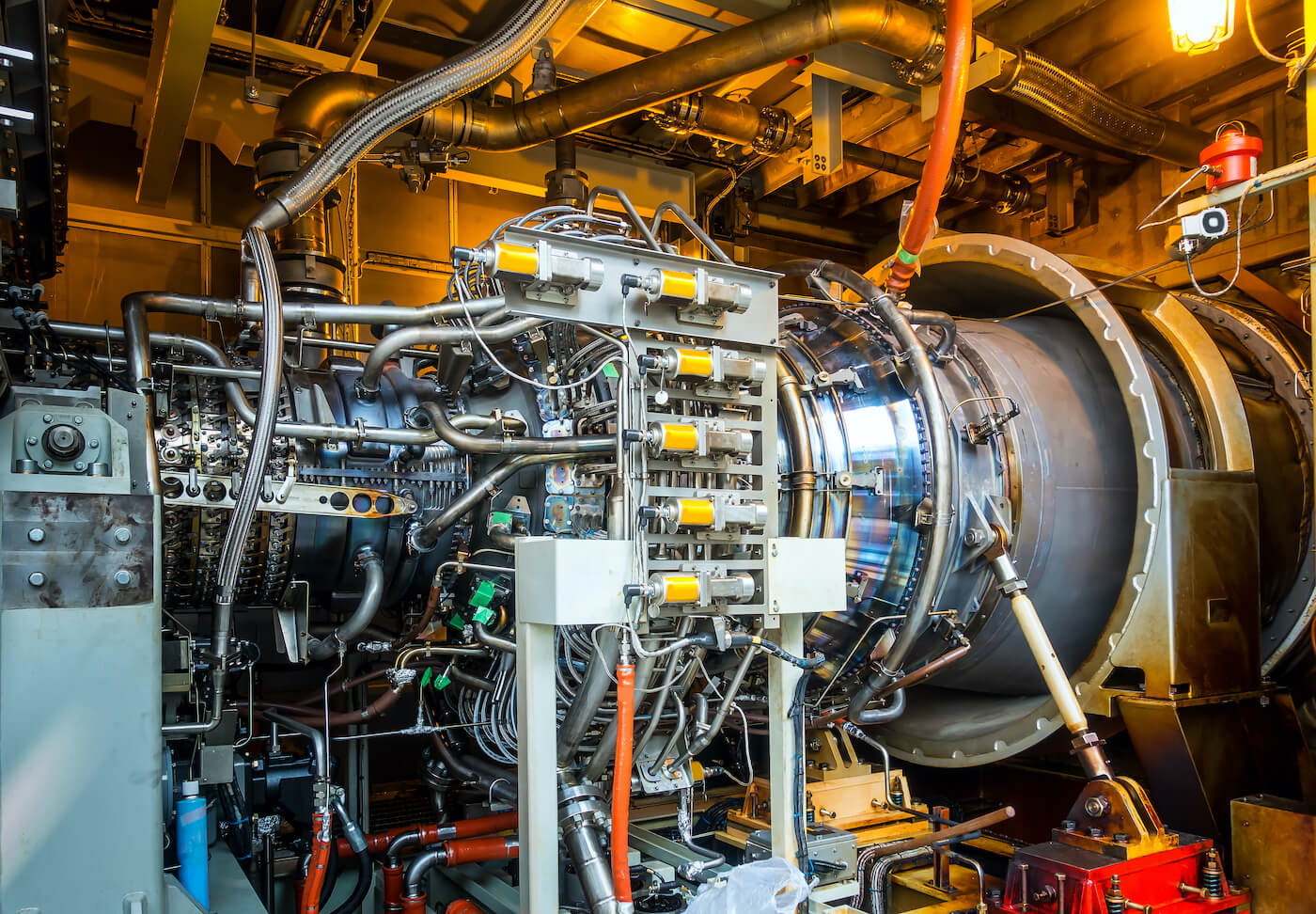

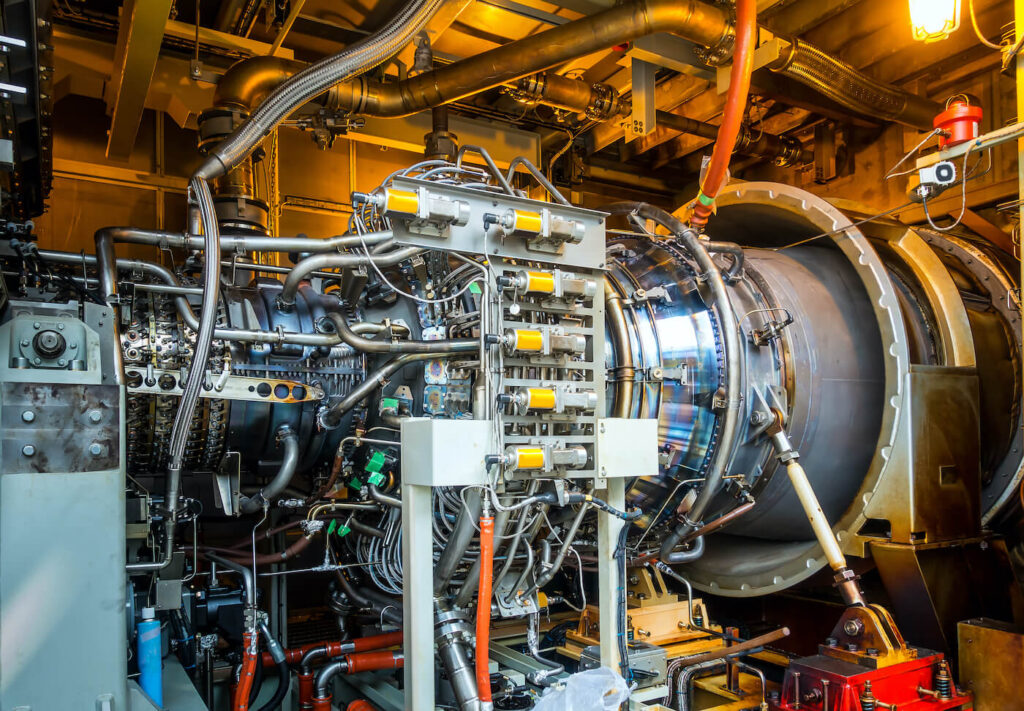

Turbine enclosures house some of the most powerful and high-energy equipment used in power generation and industrial processes. Whether for gas turbines, steam turbines, or turbine-driven compressors, these enclosures concentrate heat, fuel, lubrication systems, and electrical infrastructure within confined spaces.

Omniguard provides high-performance flame and gas detection products engineered to operate reliably inside turbine enclosures, where early detection is critical to preventing severe equipment damage and extended downtime.

Under 60 seconds

a turbine enclosure fire can escalate from ignition to severe damage.

Up to 70%

reduction in fire damage when early flame or gas detection is in place

Why turbine enclosures represent a concentrated fire risk

Unlike open turbine installations, enclosed turbine systems trap heat, vapors, and mechanical energy within a limited space. Fuel gas lines, oil lubrication systems, hot turbine casings, exhaust components, and electrical equipment all exist side by side.

A small fuel leak, oil spray, or overheated bearing can ignite almost instantly when exposed to hot surfaces or electrical sparks. Because airflow inside enclosures is controlled and often recirculated, flammable gas or oil mist can accumulate rapidly if a leak occurs.

Once a fire starts inside a turbine enclosure, heat release is intense and escalation can be extremely fast, often leaving only seconds for detection and response.

Detection technology engineered for silane conditions

Turbine enclosures present challenging detection conditions: high airflow, vibration, reflective metal surfaces, exhaust heat, and limited access for maintenance. Detection equipment must react instantly while avoiding false alarms from hot components, lighting, or exhaust turbulence.

Omniguard flame detectors provide rapid hydrocarbon flame detection within turbine enclosures, even in environments with strong airflow and intense background heat. Gas detectors monitor for fuel leaks and vapor formation around valves, manifolds, and supply lines before explosive concentrations can develop.

Our detection products support:

- Fast response time and long detection distance

- Wide viewing angles

- Designed for easy cleaning and maintenance

- All models are available with Aluminum or Stainless-Steel housing

- Worldwide service and support network

What a reliable turbine enclosure detection strategy must deliver

A dependable detection strategy for turbine enclosures must identify both gas accumulation and flame formation within seconds. Detection must remain accurate despite airflow turbulence, radiant heat, exhaust plumes, and reflective steel structures.

Equally important is integration with turbine shutdown systems, fuel isolation valves, ventilation control, and emergency alarms. When an ignition or leak is detected, response actions must occur immediately and automatically.

False alarms must also be minimized, as unnecessary turbine trips can create significant operational and grid-level consequences.

Contact us

If you need flame or gas detection products tailored for silane storage or pyrophoric gas applications, we’re here to help.

Contact us and we’ll guide you toward the right Omniguard detectors for your silane facility.

Additional Resources

Articles

Trusted Half a Century and How OmniGuard Leads Flame and Gas Detection Innovation >

From Hangars to Hydrogen and OmniGuard’s Expertise in High Stakes Environments >

Meet the Models and Choosing Between OmniGuard’s 660 760 and 860 Flame Detectors >

Precision Tested and How OmniGuard’s 540 545 Test Sources Ensure Detector Reliability >