GAS STORAGE

Flame & Gas Detection for High-Pressure and Bulk Gas Storage Facilities

Gas storage facilities play a critical role in stabilizing energy supply, supporting industrial operations, and ensuring continuity across distribution networks. Whether storing natural gas, hydrogen, biogas, or other flammable gases, these facilities operate with large volumes of compressed or pressurized fuel in both surface and underground installations.

Omniguard provides high-performance flame and gas detection products engineered to deliver early warning in gas storage environments where rapid ignition and large-scale escalation can occur within moments.

$2–10 million

typical cost range for damage and downtime after a serious gas-storage incident

More than 50%

of incidents occur during injection, withdrawal, or maintenance activities

Why gas storage represents one of the highest fire-risk categories

Unlike traditional industrial plants, wastewater facilities generate combustible gases as a natural bUnlike many process environments, gas storage facilities contain vast quantities of fuel in a concentrated form. A single leak can release large amounts of flammable gas in a short time, forming explosive clouds that may travel far beyond the original source.

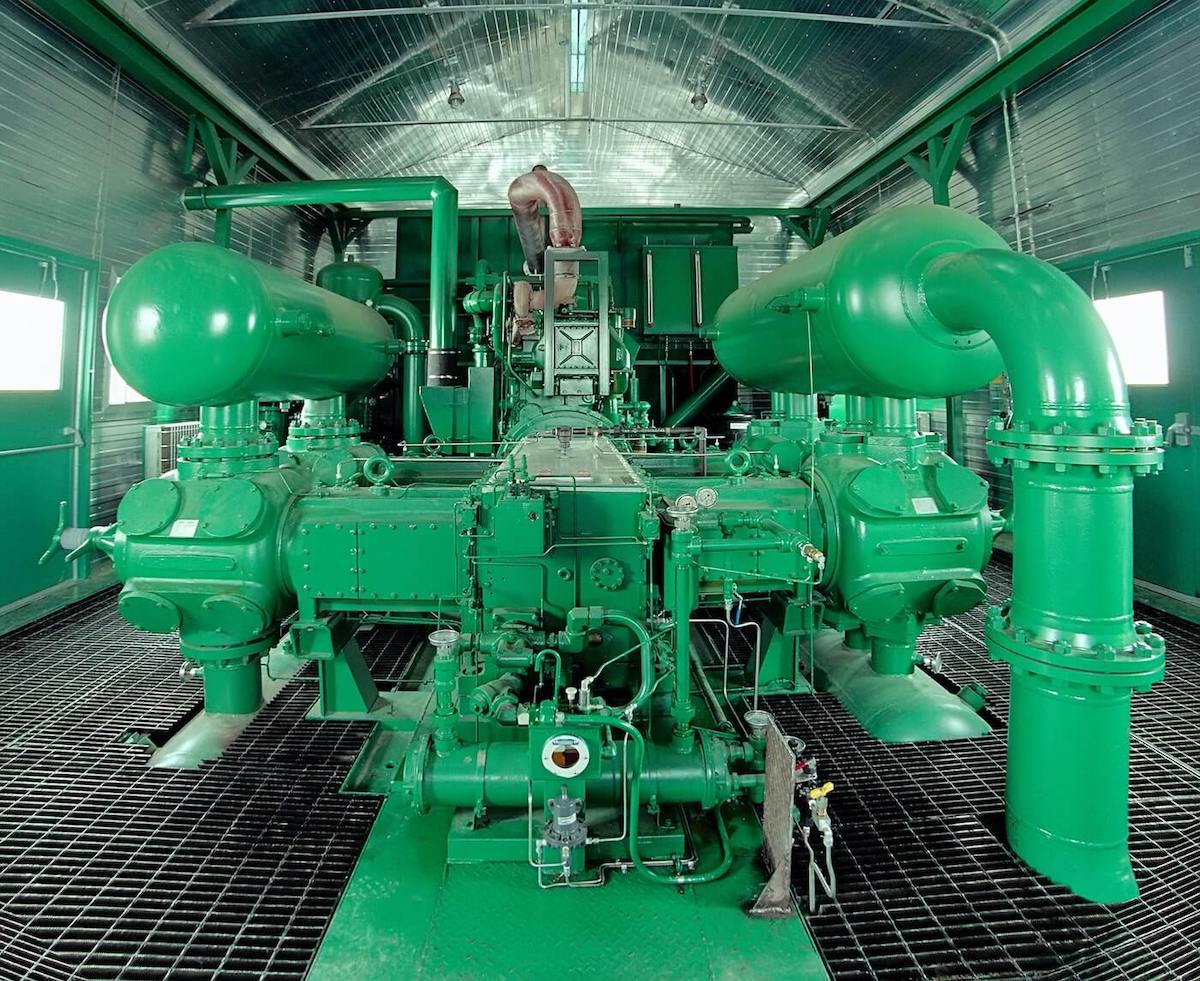

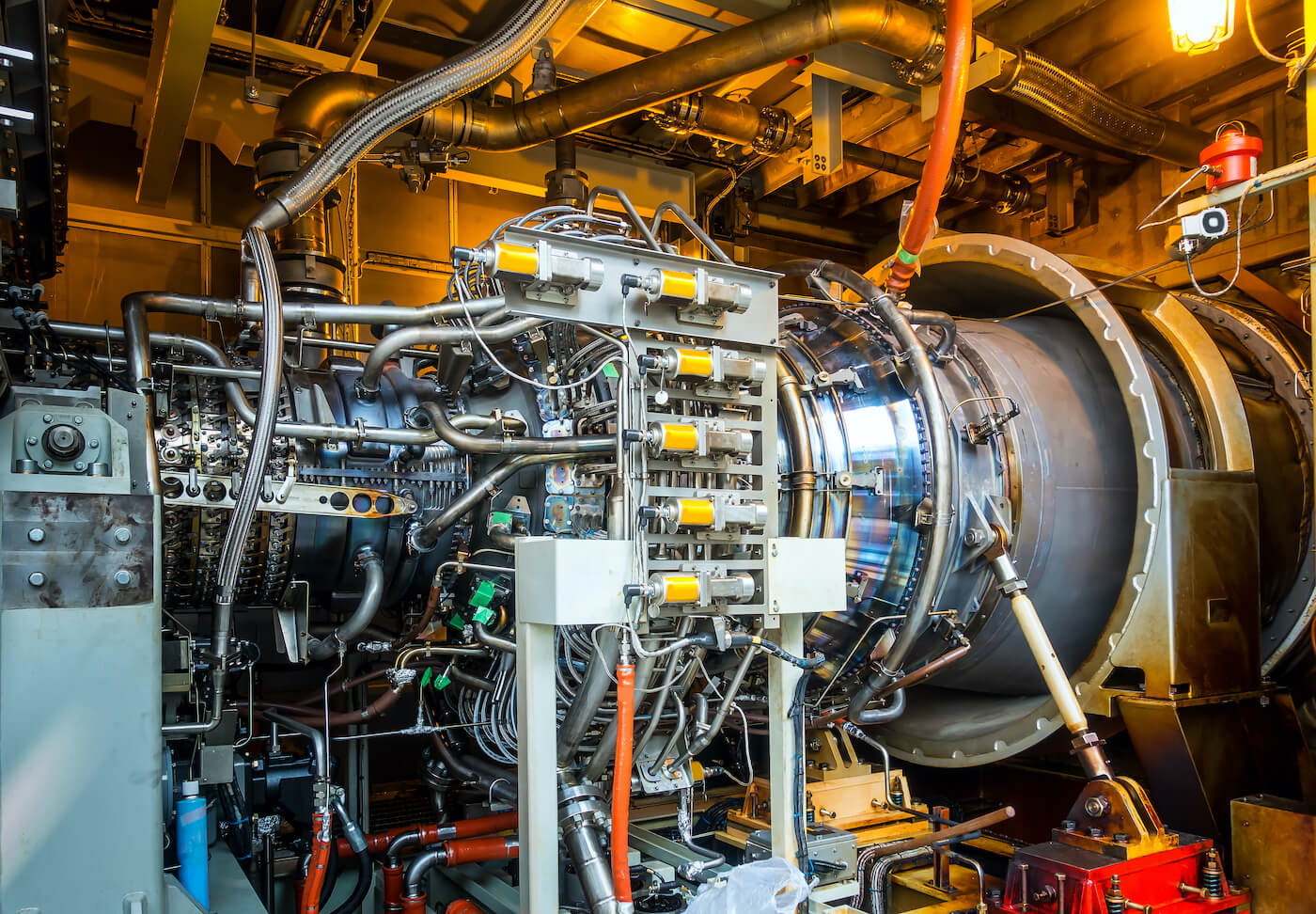

Pressure vessels, compressors, injection and withdrawal systems, valves, and extensive piping networks all introduce potential leak points. In surface storage areas, weather conditions such as wind, heat, and low temperatures influence gas dispersion and detection reliability. In underground storage, confined spaces and limited ventilation increase the consequences of any gas accumulation.

Because ignition sources can include static electricity, electrical equipment, hot surfaces, or mechanical friction, early gas and flame detection becomes the primary barrier against major incidents.

Detection technology designed for wastewater conditions

Gas storage facilities demand detection equipment that performs under pressure, in corrosive atmospheres, across wide outdoor areas, and inside confined underground installations. Detection must remain accurate despite airflow variations, temperature shifts, and background interference.

Omniguard gas detectors continuously monitor for combustible gases around storage vessels, valve stations, compressor halls, injection wells, and pipe galleries. Flame detectors provide fast recognition of ignition events in open yards, compressor areas, and surface process zones.

All Omniguard products for gas storage applications are designed for long-term stability in hazardous areas.

Our detection products support:

- Fast response time and long detection distance

- Wide viewing angles

- Designed for easy cleaning and maintenance

- All models are available with Aluminum or Stainless-Steel housing

- Worldwide service and support network

How incidents typically develop in gas storage facilities

Most serious gas storage incidents begin with small mechanical failures. A degraded gasket on a valve, a cracked pipe weld, or a failing compressor seal may start releasing gas slowly and silently. Over time, gas concentrations can reach explosive limits without any visible warning.

Injection and withdrawal cycles add additional stress to equipment as pressure and temperature change rapidly. During these transient conditions, leak probability increases significantly.

Above-ground installations face added challenges from corrosion, vibration, and weather exposure, while underground caverns, pipe galleries, and wellheads concentrate risk in confined volumes.

Once ignition occurs, escalation is often immediate and severe due to the high energy content of stored gas.

What a reliable gas-storage detection strategy must deliver

A dependable detection strategy must identify gas accumulation before explosive limits are reached and react instantly if ignition occurs. Detection must function reliably in both open-air and confined installations, resist false alarms caused by weather or reflections, and remain operational under continuous vibration and pressure cycling.

Equally important is seamless integration with isolation valves, compressor shutdowns, ventilation controls, and site-wide emergency systems. When detection occurs, the response must be automatic, fast, and coordinated.

Omniguard detection products are engineered to deliver this level of performance in some of the most demanding high-energy storage environments.

Contact us

If you need flame or gas detection products tailored for silane storage or pyrophoric gas applications, we’re here to help.

Contact us and we’ll guide you toward the right Omniguard detectors for your silane facility.

Additional Resources

Articles

Trusted Half a Century and How OmniGuard Leads Flame and Gas Detection Innovation >

From Hangars to Hydrogen and OmniGuard’s Expertise in High Stakes Environments >

Meet the Models and Choosing Between OmniGuard’s 660 760 and 860 Flame Detectors >

Precision Tested and How OmniGuard’s 540 545 Test Sources Ensure Detector Reliability >