COMPRESSOR STATIONS

Protecting Compressor Stations with Omniguard

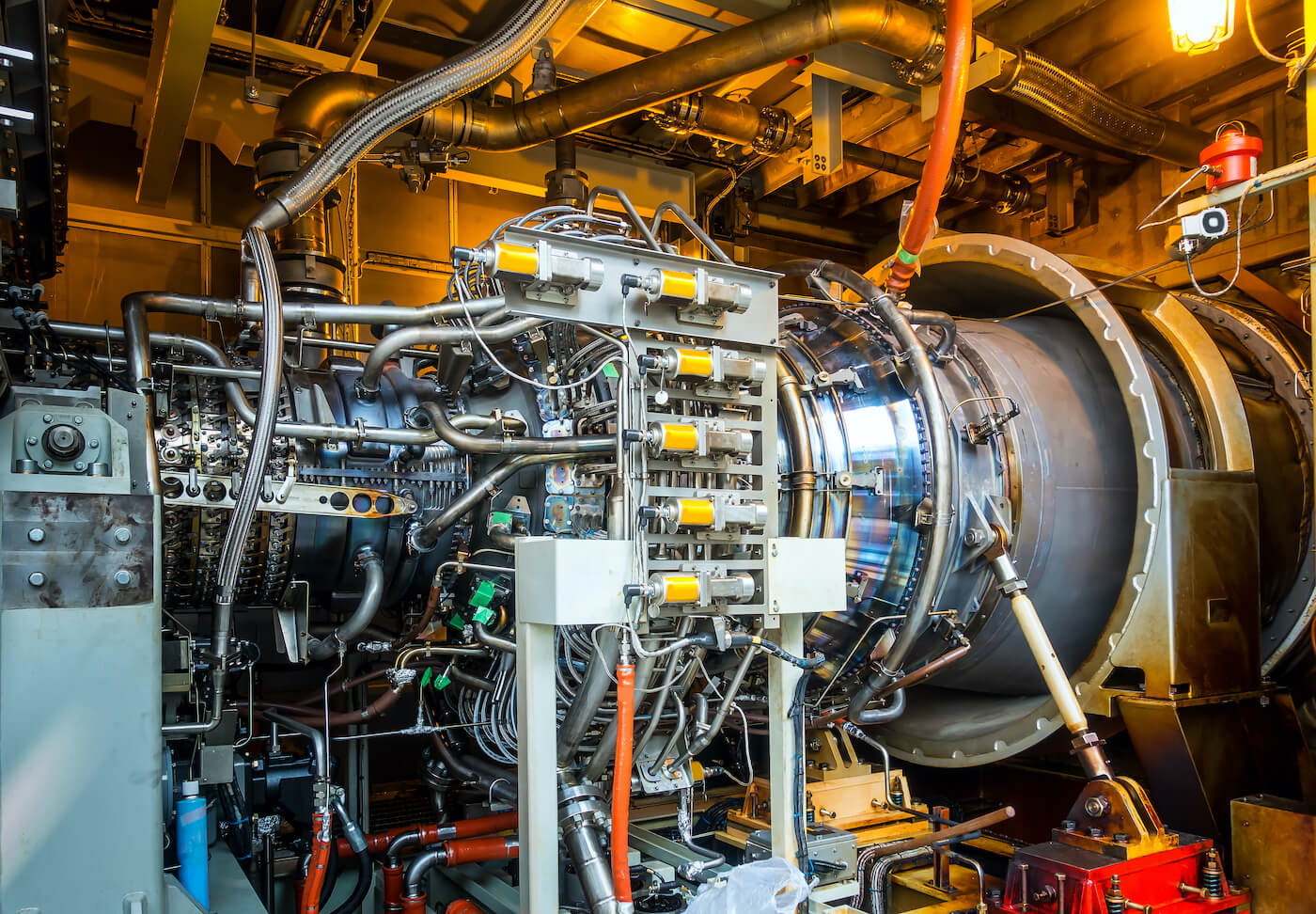

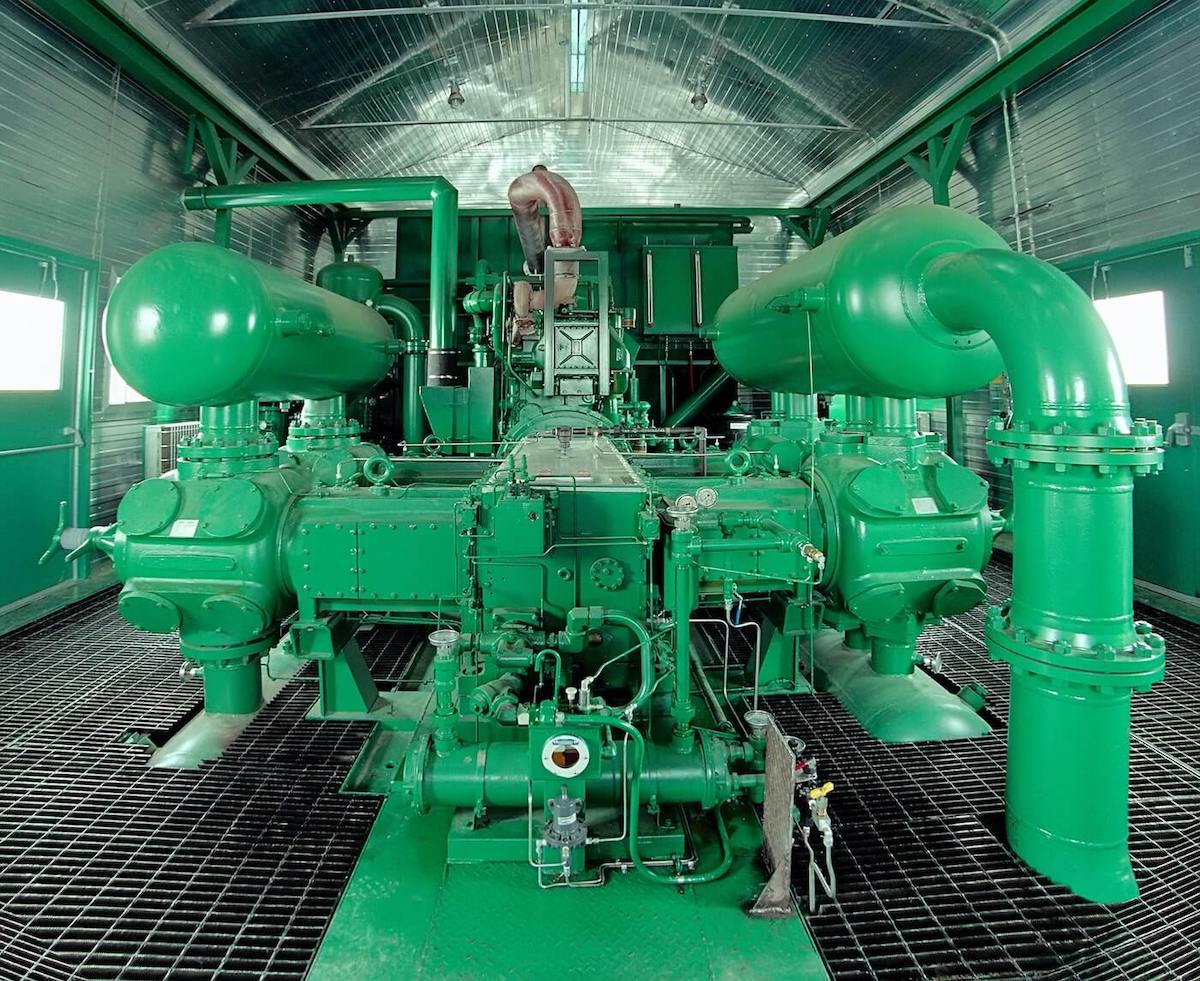

Compressor stations operate with high pressures, hot surfaces, lubricants, and flammable gases — an environment where even small deviations can turn into major fire events.

To support the protection of these critical facilities, Omniguard provides high-performance detection products designed for demanding industrial conditions.

Our flame, gas, and smoke detectors help facility owners and system integrators build reliable fire-protection systems that react early, withstand harsh environments, and reduce the risk of escalation..

70 %

of compressor-related fires are linked to overheating or lubrication failures.

80 %

Early detection reduces damage by up to 80% in machinery-related fire events.

Why compressor stations require advanced detection

Compressor stations combine rotating machinery, electrical components, and pressurized gases. This creates a fire risk profile that standard building detectors often cannot handle.

Key challenges include:

- Hot surfaces and friction points becoming ignition sources

- Oil mist from lubricant systems igniting rapidly

- Gas leaks forming explosive atmospheres

- Difficult visibility around machinery

- Vibrations and contaminants affecting detection performance

- Because of these conditions, fast and reliable detection is essential to support any fire-protection strategy.

The Omniguard solution for compressor stations

Omniguard provides high-performance detection and integrated suppression control, built to meet the harsh conditions of compressor environments. The system is designed to minimize risk and equipment damage by enabling rapid and reliable response.

Typical Risks in Compressor Stations:

- Overheating of motors, bearings, or compressor housings

- Oil mist ignition from lubrication systems

- Gas leaks (methane, process gases, refrigerants)

- Electrical faults in motors and control cabinets

- Pressure-related mechanical failures

- Accumulation of flammable vapors

- Harsh environmental conditions: vibration, dust, heat

A detection solution for compressor stations should:

- Detect flames, gas releases, smoke, and abnormal heat early

- Operate reliably despite vibration, heat, and airborne contaminants

- Minimize false alarms while reacting quickly to real threats

- Integrate with shutdown systems, alarms, and suppression

- Support compliance with relevant industrial and safety standards

Omniguard detectors are designed to meet these demands — providing dependable detection in environments where response time is crucial.

Additional Resources

Articles

Trusted Half a Century and How OmniGuard Leads Flame and Gas Detection Innovation >

From Hangars to Hydrogen and OmniGuard’s Expertise in High Stakes Environments >

Meet the Models and Choosing Between OmniGuard’s 660 760 and 860 Flame Detectors >

Precision Tested and How OmniGuard’s 540 545 Test Sources Ensure Detector Reliability >