MANUFACTURING INDUSTRY

Detection Technologies for Production Plants, Machinery Halls & Industrial Processes

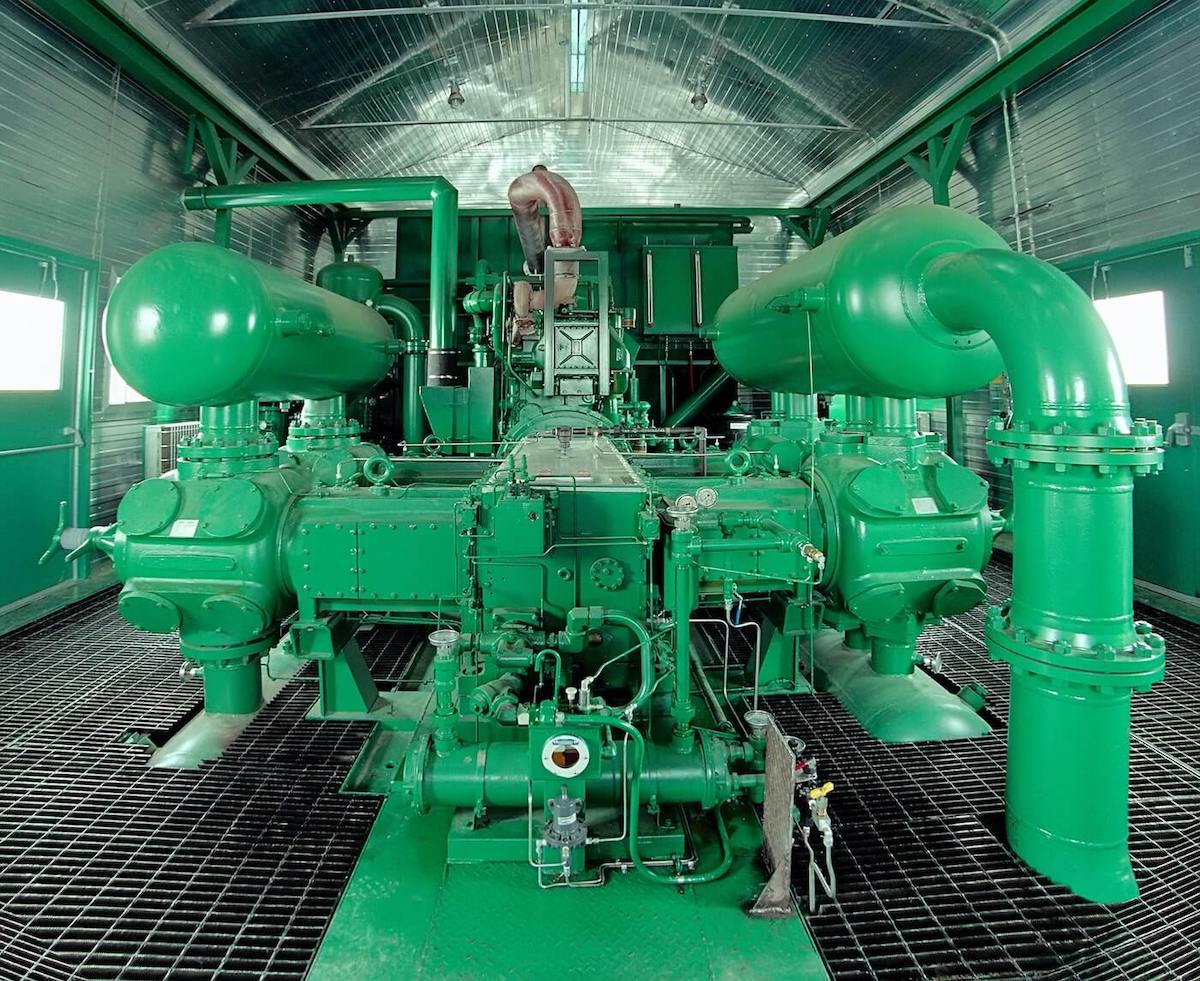

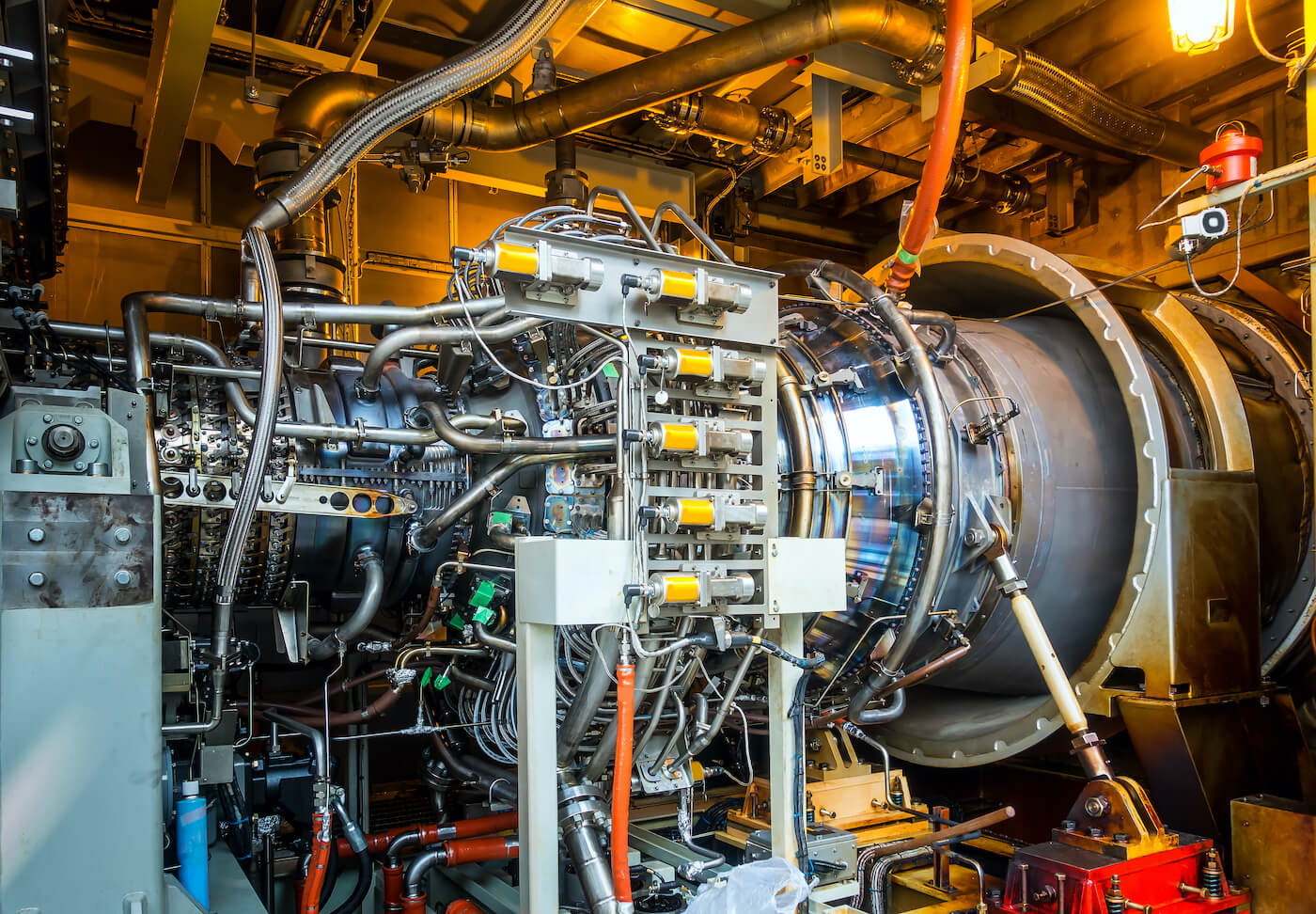

Manufacturing environments vary widely in layout, processes and equipment, but they share a common challenge: the presence of ignition sources combined with combustible materials and continuous machinery operation. From production lines and assembly areas to mixing halls, packaging zones and automated systems, manufacturing sites require fast, dependable fire and gas detection to maintain safety and operational continuity.

30–50%

of industrial fires originate from mechanical or electrical failures.

25–35%

reduction in equipment loss when fires are detected in their initial phase.

Fire risks shaped by machinery, materials and continuous operation

Manufacturing sites often run long shifts, high-speed machinery and automated processes that leave little room for error. Equipment friction, overheating components, electrical faults or malfunctioning drives can all become ignition points. Raw materials — plastics, solvents, dust, chemicals, paper, textiles or oils — can intensify fire spread if not identified early.

In addition, many production lines involve localized heat sources, welding operations, curing ovens or presses, which require sensitive yet stable detection solutions that can distinguish real fires from normal process activity.

Detection products tailored to manufacturing environments

The durability of Omniguard products makes them suitable for robotic cells, conveyor systems, machinery bays, ventilation ducts, assembly areas and critical equipment rooms.

Our detection products support:

- Fast response time and long detection distance

- Wide viewing angles

- Designed for easy cleaning and maintenance

- All models are available with Aluminum or Stainless-Steel housing

- Worldwide service and support network

How incidents commonly develop in manufacturing settings

The earliest signs of a developing fire in a plant are often subtle: a bearing running hot, dust igniting inside a machine housing, a spark from maintenance work, or smoke trapped in enclosed equipment. While small at first, these events can escalate rapidly — particularly in conveyor systems, robotic cells, electrical cabinets or areas with combustible dust.

Packaging lines, drying zones, and areas where solvents or flammable liquids are stored add additional hazard layers. In many cases, fires occur out of direct view: behind panels, inside machinery, or in overhead cable trays. Effective detection must therefore reach into areas that operators cannot easily monitor.

Supporting a wide range of production environments

Modern manufacturing includes an enormous range of processes — plastics, electronics, automotive, metalworking, food production, textiles, packaging and more. Omniguard detectors are adaptable to all of these settings, integrating easily into existing fire and gas detection systems.

Whether used around machinery clusters, process cells, raw-material storage areas or automated production sections, our detectors help maintain a safer working environment and reduce the risk of costly interruptions

Additional Resources

Articles

Trusted Half a Century and How OmniGuard Leads Flame and Gas Detection Innovation >

From Hangars to Hydrogen and OmniGuard’s Expertise in High Stakes Environments >

Meet the Models and Choosing Between OmniGuard’s 660 760 and 860 Flame Detectors >

Precision Tested and How OmniGuard’s 540 545 Test Sources Ensure Detector Reliability >