PRODUCTION PLATFORM

Fire & Gas Detection for Offshore Oil and Gas Production

Offshore production platforms operate in some of the harshest and highest-risk industrial environments in the world. With flammable hydrocarbons under pressure, confined process areas, rotating equipment, and weather exposure, these platforms require detection technologies that react instantly and operate reliably at all times.

70–80%

of offshore fire incidents originate from hydrocarbon leaks.

>50%

of offshore downtime events are linked to early-stage mechanical or electrical failures.

Offshore hazards shaped by pressure, confinement & exposure

Unlike onshore facilities, production platforms combine high-energy processes with limited escape routes and constant environmental stress. Waves, wind, salt spray, and vibration place heavy demands on all equipment. Meanwhile, hydrocarbon extraction and separation systems operate under high pressure and elevated temperature.

Leaks from process vessels or rotating machinery can ignite quickly, and enclosed module layouts mean even small fires can escalate rapidly if not detected in time. Because platforms operate 24/7 far from land, fast detection directly supports life safety and operational continuity.

Detection products built for offshore environments

Omniguard detectors are designed for high-risk, high-exposure environments. Offshore installations demand sensors that operate correctly despite bright sunlight, salt air, vibration, moisture, and thermal cycling.

Our flame detectors deliver rapid recognition of hydrocarbon fires even across long distances and reflective surfaces. Gas detectors identify explosive atmospheres around processing modules, risers, pump rooms, and wellhead equipment. These technologies help reduce escalation risk by enabling operators to respond before conditions become critical.

Our detection products support:

- Fast response time and long detection distance

- Wide viewing angles

- Designed for easy cleaning and maintenance

- All models are available with Aluminum or Stainless-Steel housing

- Worldwide service and support network

Where ignition risks emerge on production platforms

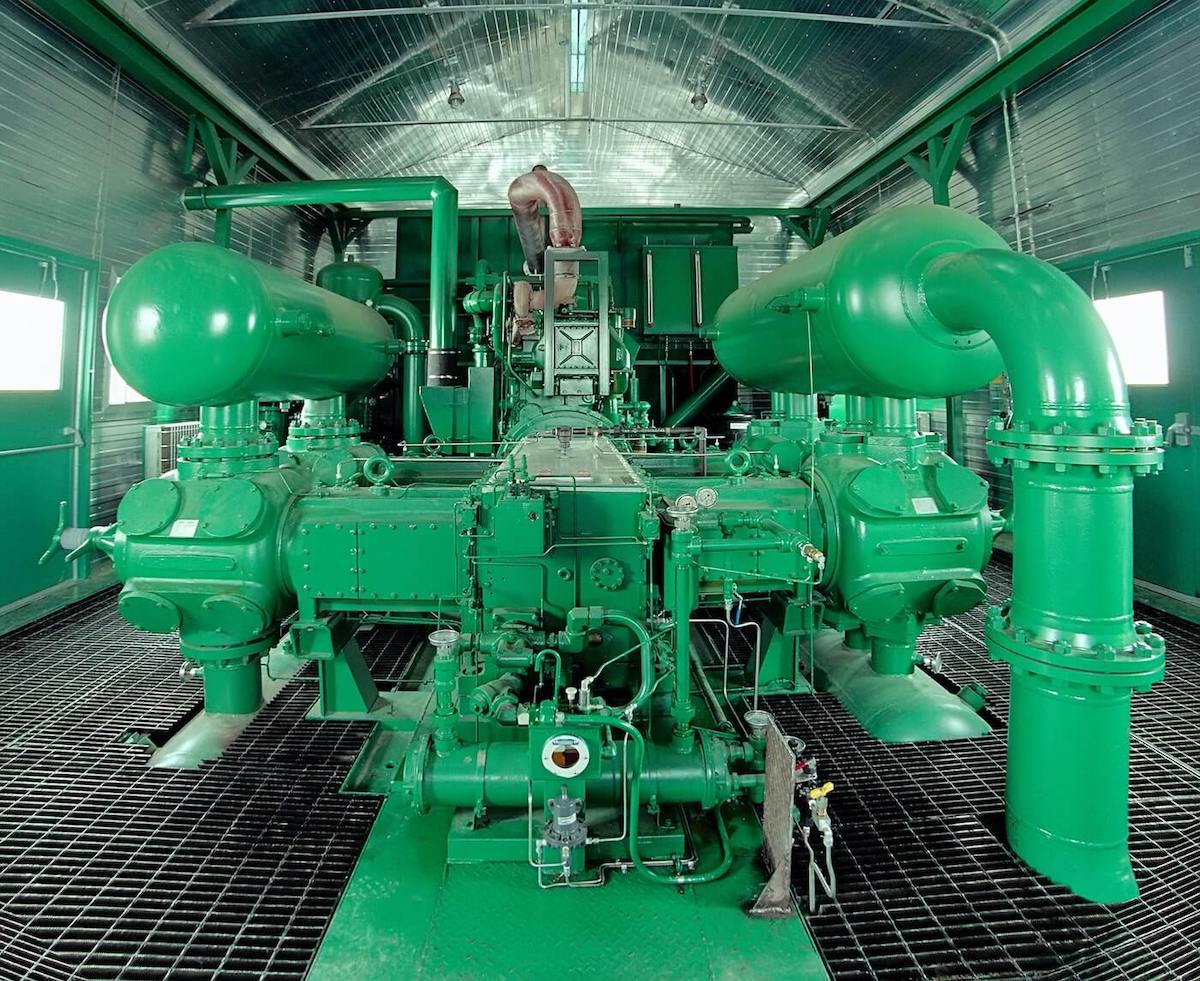

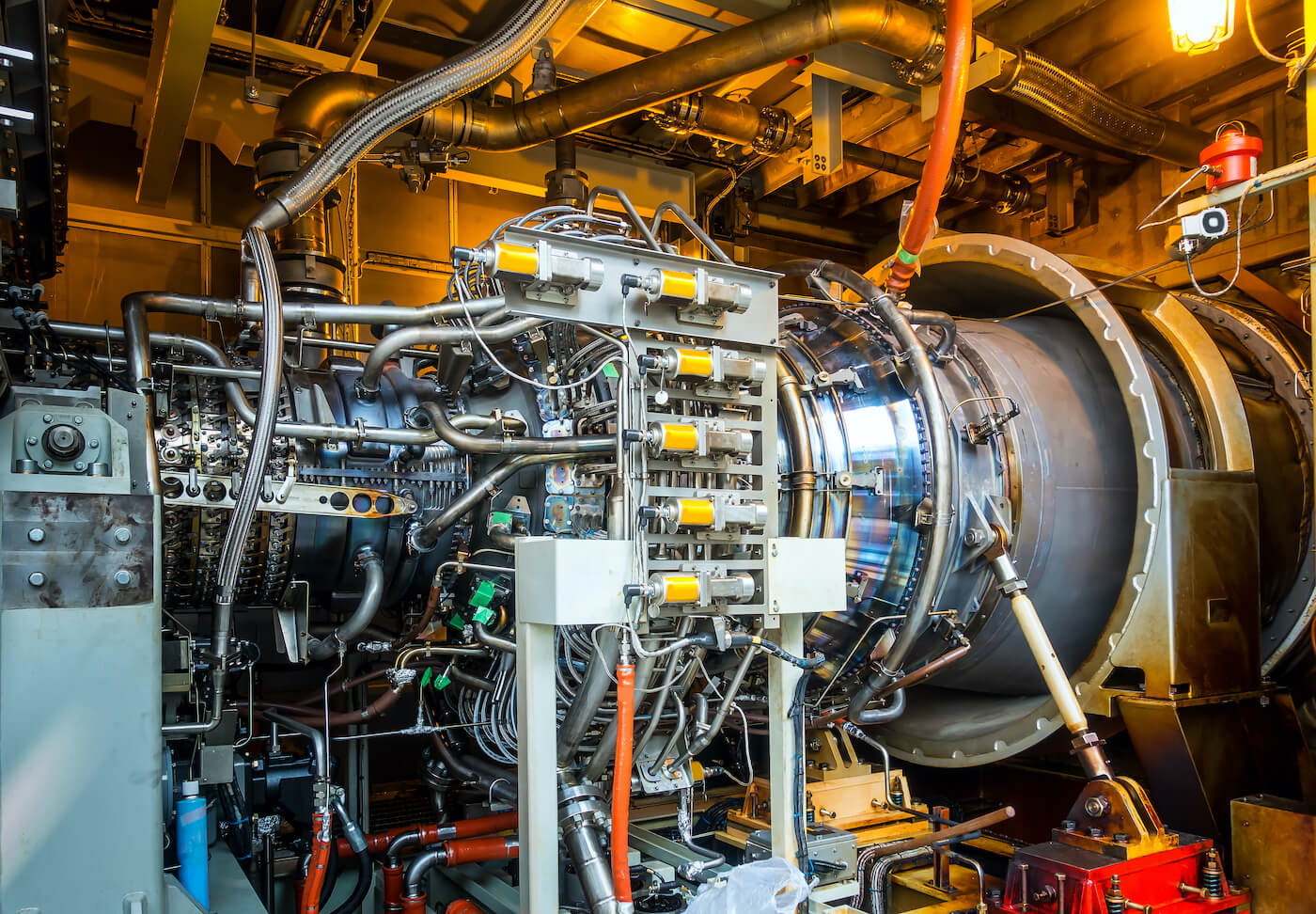

Most offshore fire events originate in areas with dense equipment and intense process conditions. Separation units, compressors, gas treatment systems, heaters, and pump skids all handle fuels capable of ignition. Gas leaks in tight spaces, liquid carryover near hot surfaces, and friction or overheating in mechanical equipment can result in flame formation with little warning.

Drilling areas, riser decks, wellheads, and flare systems add further risk zones. Even living quarters and electrical rooms must be monitored, as fires in non-process areas can disrupt essential infrastructure. The combination of confined modules and high hydrocarbon inventory makes early detection a critical layer of protection.

What offshore detection systems must achieve

Detection on production platforms must be fast, stable, and highly resistant to interference from weather, vibration, and operational noise. Sensors need to differentiate real fire or gas events from reflections, flare-related light, or exhaust heat.

They must also integrate seamlessly with platform safety systems — including deluge activation, blowdown valves, ventilation isolation, and general platform alarms. Given the offshore environment’s unforgiving nature, reliability and low false-alarm rates are essential.

Additional Resources

Articles

Trusted Half a Century and How OmniGuard Leads Flame and Gas Detection Innovation >

From Hangars to Hydrogen and OmniGuard’s Expertise in High Stakes Environments >

Meet the Models and Choosing Between OmniGuard’s 660 760 and 860 Flame Detectors >

Precision Tested and How OmniGuard’s 540 545 Test Sources Ensure Detector Reliability >