PUMP STATIONS PIPELINE

Fire & Gas Detection for Critical Fuel Transport Infrastructure

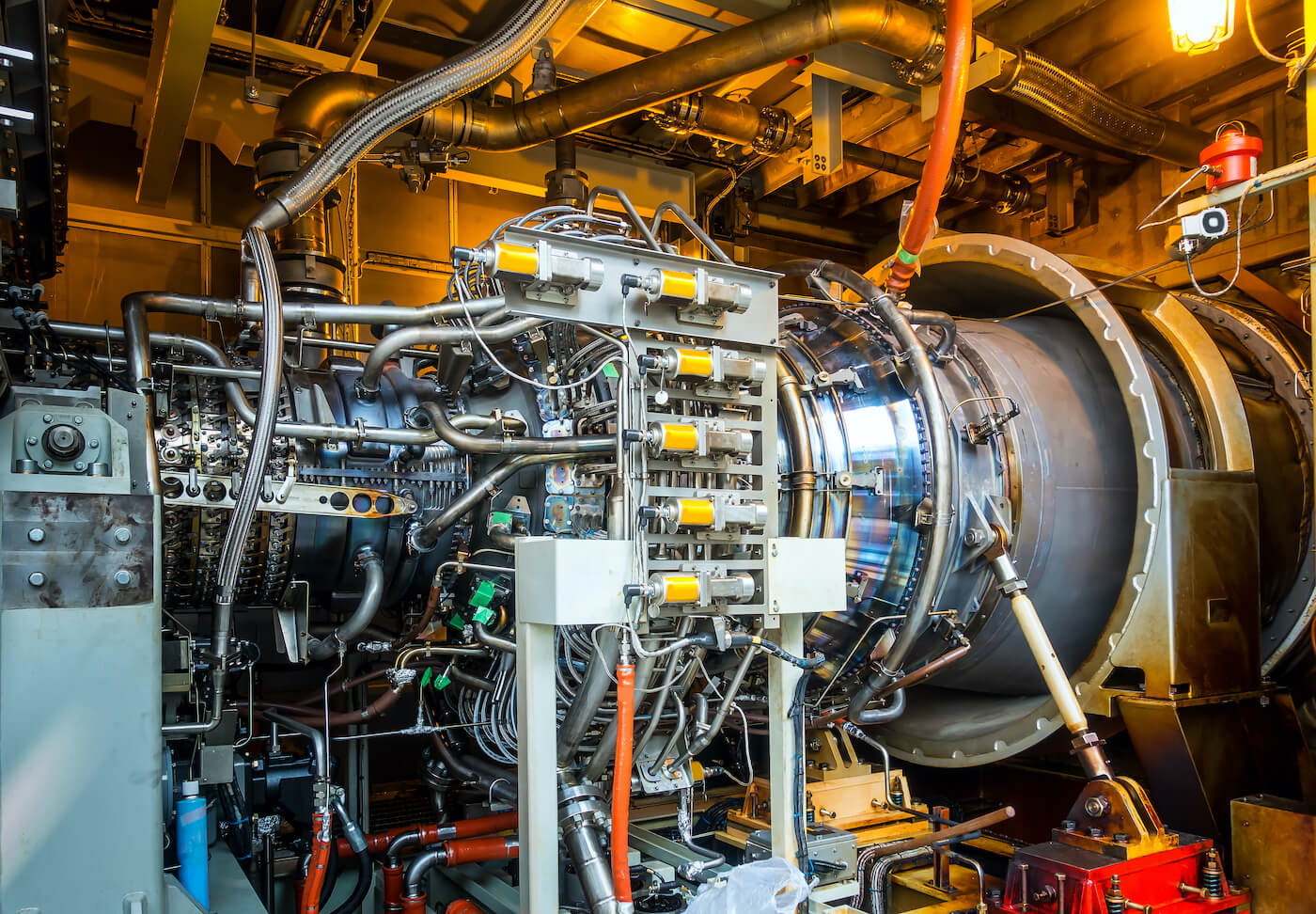

Offshore production platforms operate in some of the harshest and highest-risk industrial environments in the world. With flammable hydrocarbons under pressure, confined process areas, rotating equipment, and weather exposure, these platforms require detection technologies that react instantly and operate reliably at all times.

1–3 minutes

typical escalation time for an ignition in an enclosed pump room.

Up to 75%

reduction in incident severity with early flame or gas detection.

Where continuous flow meets continuous risk

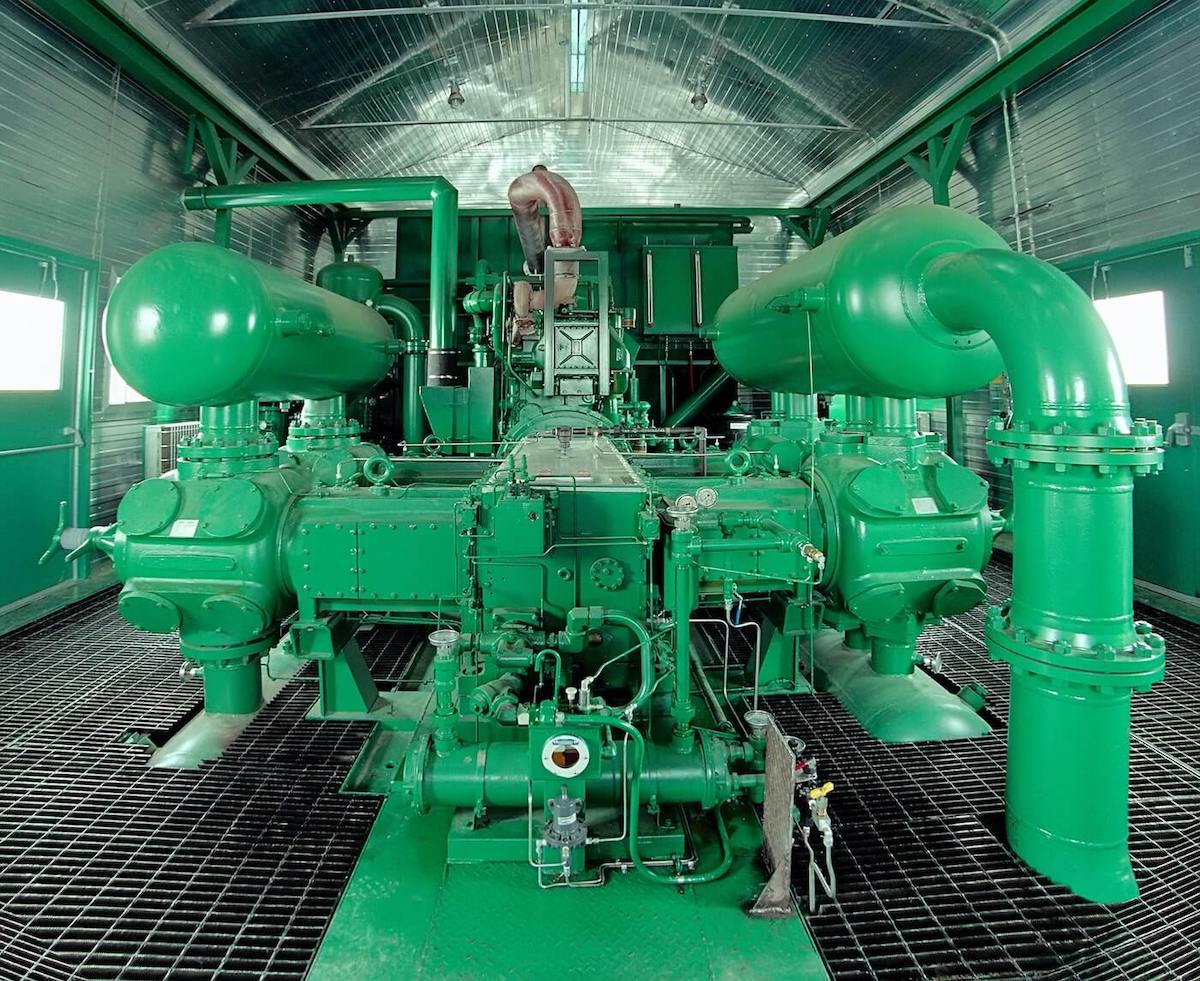

Pipeline and pump-station operations may appear simple on the surface—pressurize, transport, monitor—but the underlying risks are significant. Equipment operates for long periods with minimal downtime, meaning a worn seal, a fatigued weld, or a failing motor can release flammable gas or liquid unexpectedly.

Many stations are unmanned or only periodically inspected, so incidents may develop without on-site observation. Weather exposure, vibration, and remote locations make reliable detection technology essential for maintaining safety and operational continuity.

Detection built for demanding environments

Omniguard detection products are engineered for locations where maintenance intervals may be long and environmental conditions harsh.

Flame detectors offer fast, accurate response to ignition events—even in bright sunlight or long sightlines along a pipeline corridor. Gas detectors can identify flammable atmospheres forming in pump buildings, valve pits, or low-lying areas where vapors may accumulate.

Our detection products support:

- Fast response time and long detection distance

- Wide viewing angles

- Designed for easy cleaning and maintenance

- All models are available with Aluminum or Stainless-Steel housing

- Worldwide service and support network

How problems typically develop in pipeline and pump systems

Fire and leak events often start with small, gradual changes: a pressure irregularity, a minor drip accumulating near a pump housing, or vapor escaping at a valve stem. Over time, these small releases can form flammable gas clouds—especially in enclosed pump buildings or underground vaults.

Mechanical components, such as motors, gearboxes, and bearings, can overheat under load. If fuel or vapor is present, ignition becomes likely. Electrical faults in control cabinets or cable trenches add another potential source.

Because pipeline systems are long and often isolated, rapid automatic detection is essential to catch issues before they become major incidents.

What detection must deliver in pipeline infrastructure

Pump stations and pipelines demand detection that remains stable year-round, unaffected by weather, dust, insects, sunlight, vibration, or fluctuating temperatures.

Systems must be capable of identifying leaks quickly, communicating alarms to remote control centers, and automatically triggering safety actions such as pump shutdown or valve isolation.

False alarms must be minimized, as unnecessary shutdowns on high-capacity pipelines can cause major operational disruptions.

Additional Resources

Articles

Trusted Half a Century and How OmniGuard Leads Flame and Gas Detection Innovation >

From Hangars to Hydrogen and OmniGuard’s Expertise in High Stakes Environments >

Meet the Models and Choosing Between OmniGuard’s 660 760 and 860 Flame Detectors >

Precision Tested and How OmniGuard’s 540 545 Test Sources Ensure Detector Reliability >