TANK FARMS

Flame & Gas Detection for Bulk Storage of Flammable Liquids and Vapors

Tank farms store enormous volumes of flammable liquids and hydrocarbon products. These storage terminals — whether located at refineries, chemical plants, distribution hubs, or coastal facilities — face constant risk from vapor releases, tank overfill, pump failures, and ignition sources.

Omniguard by Firefly provides high-performance flame and gas detection products engineered specifically for tank farm environments, helping operators detect ignition or vapor formation before an incident escalates.

Over 70%

of tank farm fires originate at tank roof seals, vents, or pump areas.

$3–10 million

typical economic loss when a single storage tank is affected by fire.

Why tank farms are high-risk environments

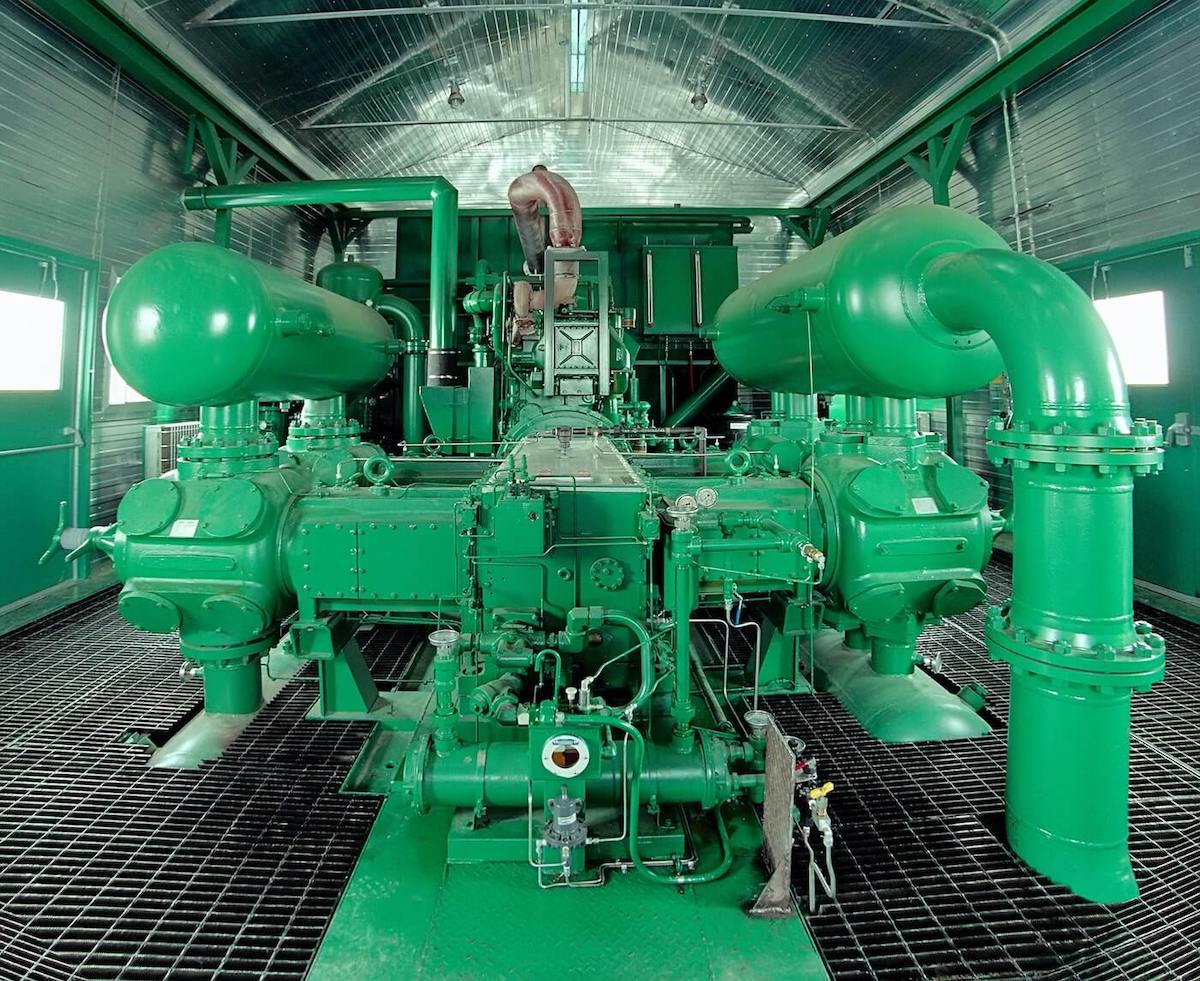

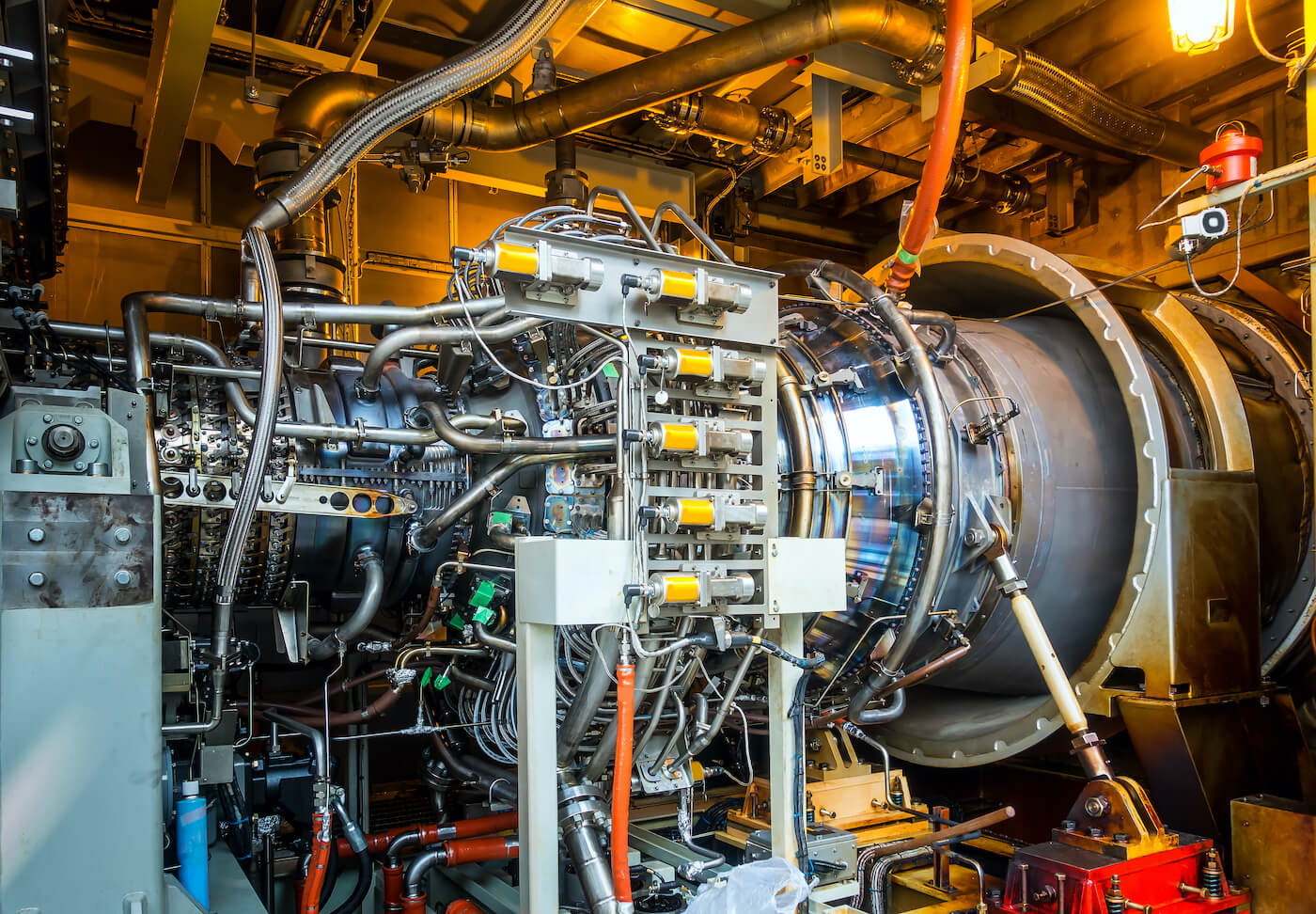

Tank farms combine large inventories of volatile fuels with outdoor weather exposure, aging equipment, and extensive piping and transfer systems. Vapors accumulate around tank vents, domes, floating roofs, and pump areas.

A small release around a tank roof seal, a faulty valve, a loading connection, or a pump seal can quickly create an explosive atmosphere — especially during hot weather or periods of heavy transfer activity.

Ignition sources such as static discharge, nearby electrical equipment, or friction from mechanical systems increase the likelihood of fires if vapors are not detected early.

Because storage volumes are large and often connected through manifold systems, early detection is the single most important step in preventing widespread damage.

Detection technology engineered for silane conditions

Omniguard detection products are engineered to perform reliably in large, open, outdoor environments where wind, sunlight, and temperature can challenge conventional sensors.

Our flame detectors provide long-range hydrocarbon flame recognition, capable of identifying fires on tank roofs, dike areas, loading bays, and transfer stations.

Gas detectors monitor for vapor buildup around tanks, piping, and pump systems, alerting operators before concentrations reach dangerous levels.

Our detection products support:

- Fast response time and long detection distance

- Wide viewing angles

- Designed for easy cleaning and maintenance

- All models are available with Aluminum or Stainless-Steel housing

- Worldwide service and support network

What a reliable detection strategy must achieve in tank farms

An effective tank farm detection approach must be capable of identifying ignition and vapor release early enough to influence emergency response. Detection must work across large open areas, resist false alarms caused by reflections and sunlight, and remain operational in extreme weather conditions.

It must also integrate seamlessly with emergency shutdown systems, pump isolation, deluge activation, and site-wide alarm networks to ensure that safety actions are automatic and immediate.

Omniguard detection products are engineered with these requirements in mind, delivering dependable performance in some of the most challenging outdoor industrial environments.

Contact us

If you need flame or gas detection products tailored for silane storage or pyrophoric gas applications, we’re here to help.

Contact us and we’ll guide you toward the right Omniguard detectors for your silane facility.

Additional Resources

Articles

Trusted Half a Century and How OmniGuard Leads Flame and Gas Detection Innovation >

From Hangars to Hydrogen and OmniGuard’s Expertise in High Stakes Environments >

Meet the Models and Choosing Between OmniGuard’s 660 760 and 860 Flame Detectors >

Precision Tested and How OmniGuard’s 540 545 Test Sources Ensure Detector Reliability >