WASTEWATER

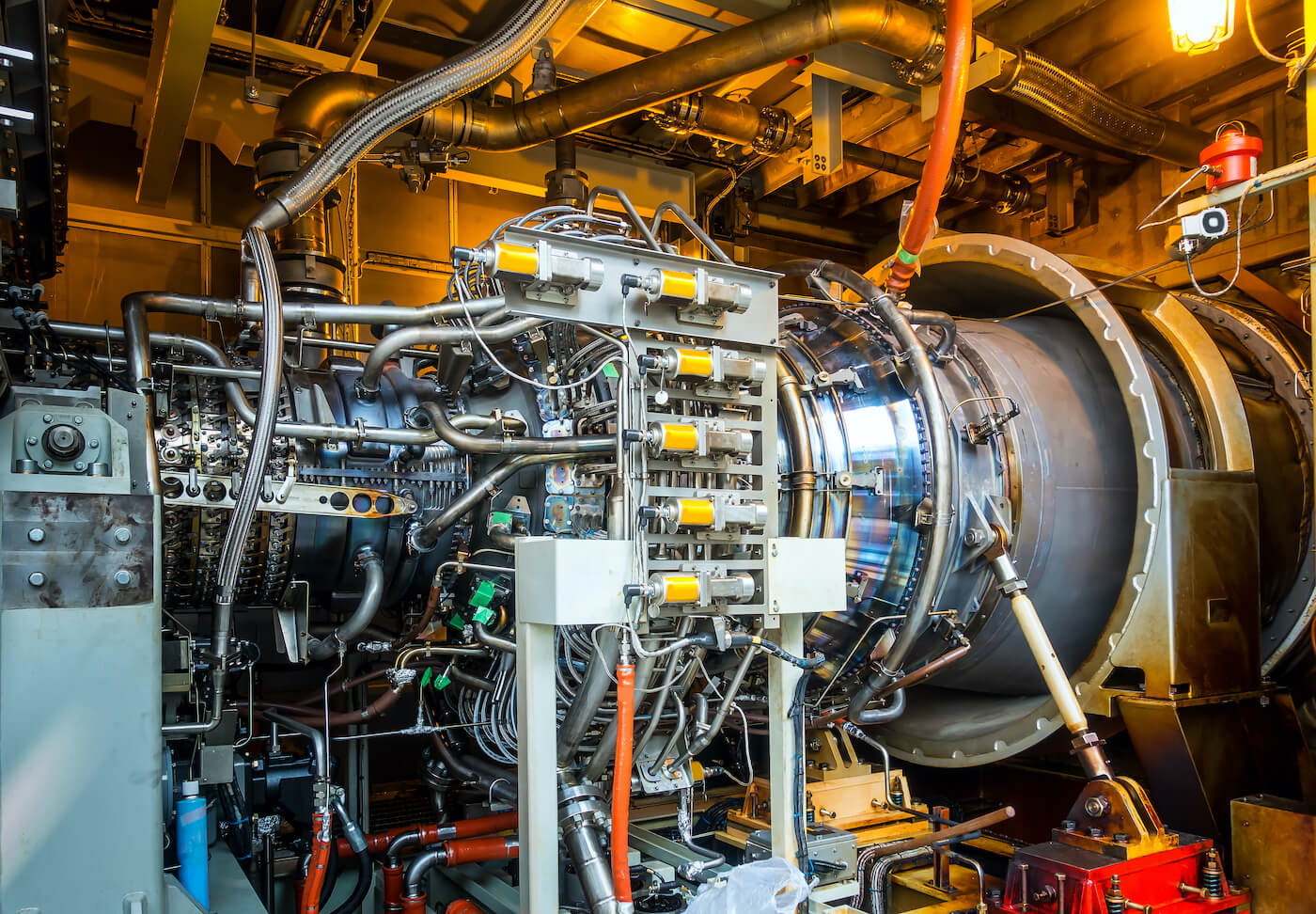

Flame & Gas Detection for Enclosed Gas and Steam Turbine Installations

Wastewater treatment plants operate at the intersection of biological processes, mechanical systems, and combustible gas generation. From inlet works and aeration basins to sludge handling, digestion, and gas utilization, these facilities continuously produce and handle flammable and toxic gases in enclosed and semi-enclosed environments.

Omniguard provides high-performance flame and gas detection products engineered to operate reliably in corrosive, humid, and gas-rich wastewater environments where early detection is essential for both safety and operational stability.

60–70%

of wastewater-related fire and explosion incidents are linked to biogas or methane accumulation

Over 30%

of serious incidents occur in digesters, gas storage systems, or gas-utilization units

Why wastewater environments present hidden fire and explosion risks

Unlike traditional industrial plants, wastewater facilities generate combustible gases as a natural by-product of biological processes. Anaerobic digestion produces methane-rich biogas, while hydrogen sulfide (H₂S) forms in multiple treatment stages. These gases can accumulate in digesters, gas storage systems, pipe galleries, pump rooms, and enclosed sludge-processing areas.

At the same time, wastewater plants operate with:

- Electrical equipment in humid conditions

- Mechanical equipment exposed to corrosion and vibration

- Enclosed basins and tunnels with limited ventilation

- Gas utilization systems connected to boilers, CHP units, and flares

A single undetected gas release near electrical equipment, hot surfaces, or rotating machinery can escalate rapidly

Detection technology designed for wastewater conditions

Wastewater facilities create some of the most challenging detection environments: high humidity, corrosive gases, constant condensation, biological contaminants, and outdoor exposure. Detection products must remain stable despite these conditions while delivering rapid response to both gas and flame events.

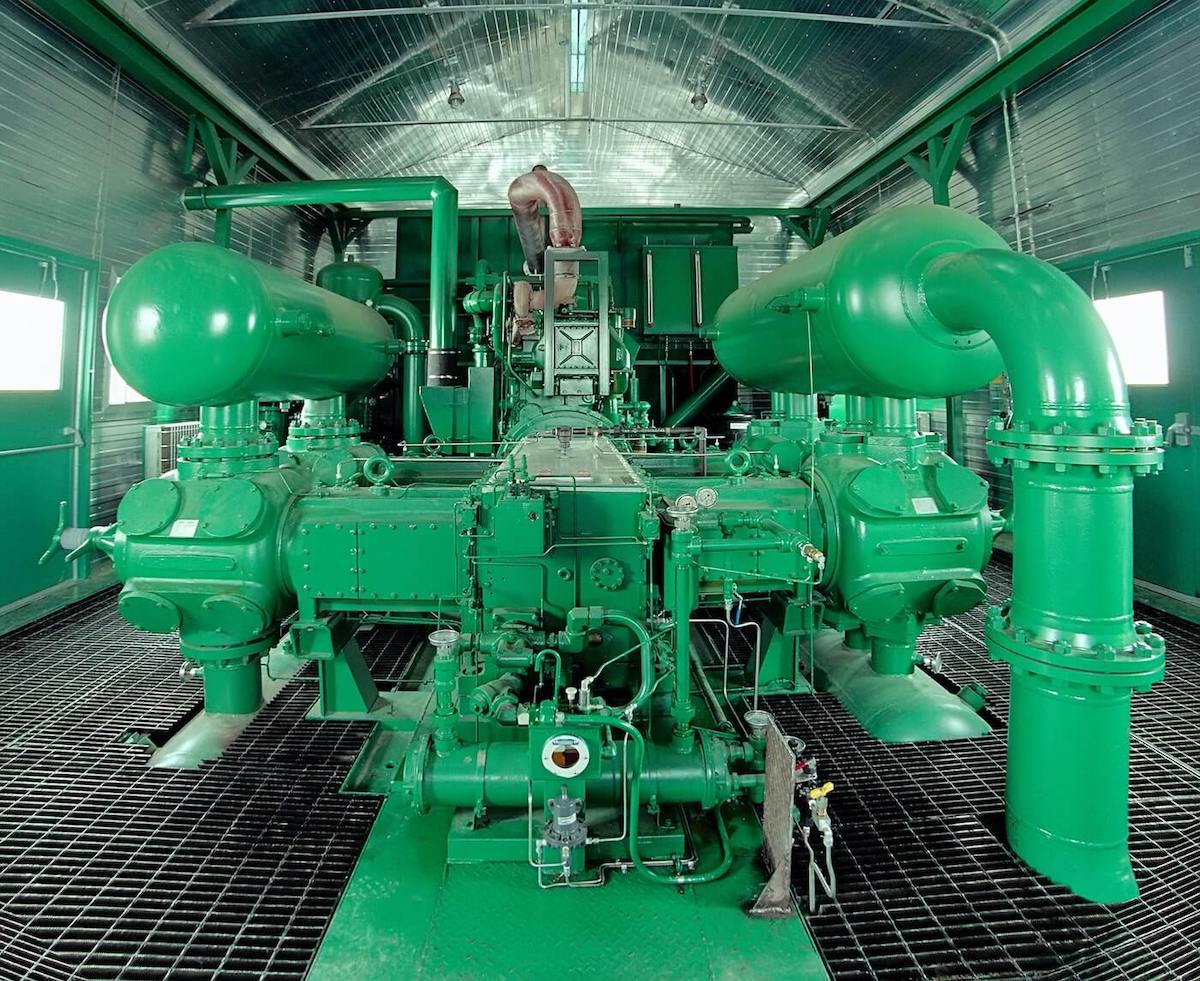

Omniguard gas detectors monitor for methane and hydrogen sulfide around digesters, gas storage vessels, compressors, pipe racks, and enclosed basins. Flame detectors provide fast ignition recognition near gas engines, boilers, CHP units, sludge dryers, and flare systems.

All Omniguard products used in wastewater environments are designed for long-term stability and low maintenance.

Our detection products support:

- Fast response time and long detection distance

- Wide viewing angles

- Designed for easy cleaning and maintenance

- All models are available with Aluminum or Stainless-Steel housing

- Worldwide service and support network

How incidents typically develop in wastewater facilities

Most wastewater-related gas and fire incidents begin with slow, difficult-to-detect changes. A leaking digester flange, a cracked biogas pipe, or a failing compressor seal may release gas gradually into enclosed spaces. Over time, gas concentrations can reach flammable or toxic levels without visible warning.

Sludge-handling areas introduce additional risks through drying processes, friction in conveyors, and dust formation. Pump stations, electrical rooms, and underground pipe galleries often act as collection points for both methane and hydrogen sulfide.

Because many of these areas are unmanned, automatic detection becomes the primary layer of protection.

What a reliable detection strategy must deliver in wastewater facilities

A dependable detection approach must identify gas buildup before explosive limits are reached and react instantly to ignition if it occurs. Detection must remain accurate in high-humidity conditions, resist corrosion, and operate reliably in both open-air and enclosed treatment zones.

Equally critical is integration with ventilation systems, gas isolation valves, emergency shutdowns, and site-wide alarm systems. When gas is detected, response actions must occur automatically and without delay.

False alarms must also be minimized, as unnecessary shutdowns in treatment processes can disrupt biological stability and overall plant performance.

Contact us

If you need flame or gas detection products tailored for silane storage or pyrophoric gas applications, we’re here to help.

Contact us and we’ll guide you toward the right Omniguard detectors for your silane facility.

Additional Resources

Articles

Trusted Half a Century and How OmniGuard Leads Flame and Gas Detection Innovation >

From Hangars to Hydrogen and OmniGuard’s Expertise in High Stakes Environments >

Meet the Models and Choosing Between OmniGuard’s 660 760 and 860 Flame Detectors >

Precision Tested and How OmniGuard’s 540 545 Test Sources Ensure Detector Reliability >