Omniguard flame detectors are known throughout the world for their outstanding quality and reliability. Since more than 50 years Omniguard detectors are being used in a wide variety of high-risk fire protection applications.

Omniguard flame detectors offer:

- UV, UV/IR and Multi-Spectrum 5IR

- Operating temperature -40° to +85˚C (-40° to +185°F)

- UV detector also in High-temp version -40° to +125˚C (-40° to +257°F)

- State of the art through-the-lens diagnostic self-test

- Fast response time and long detection distance

- Patented Fire Event Analysis (FEA) algorithm for superior False-alarm immunity

- Wide viewing angles

- Designed for easy cleaning and maintenance

- All models are available with Aluminum or Stainless-Steel housing

- FM, CSA, ATEX, IECEx, SIL2, EMC, LVD, CSFM

- Worldwide service and support network

Products

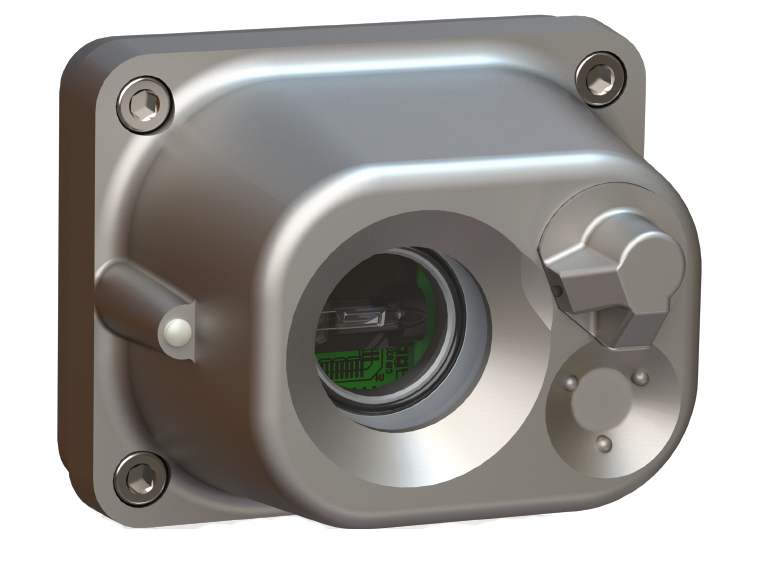

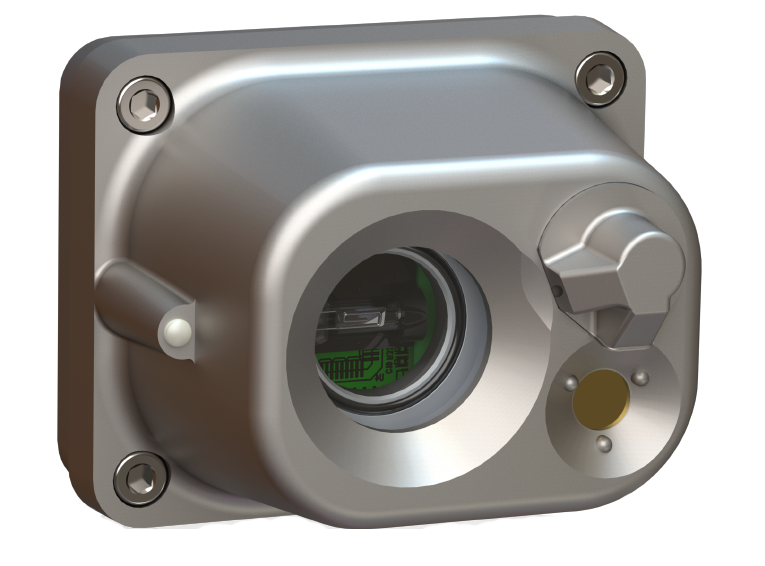

OMNIGUARD MODEL 660 – UV FLAME DETECTOR

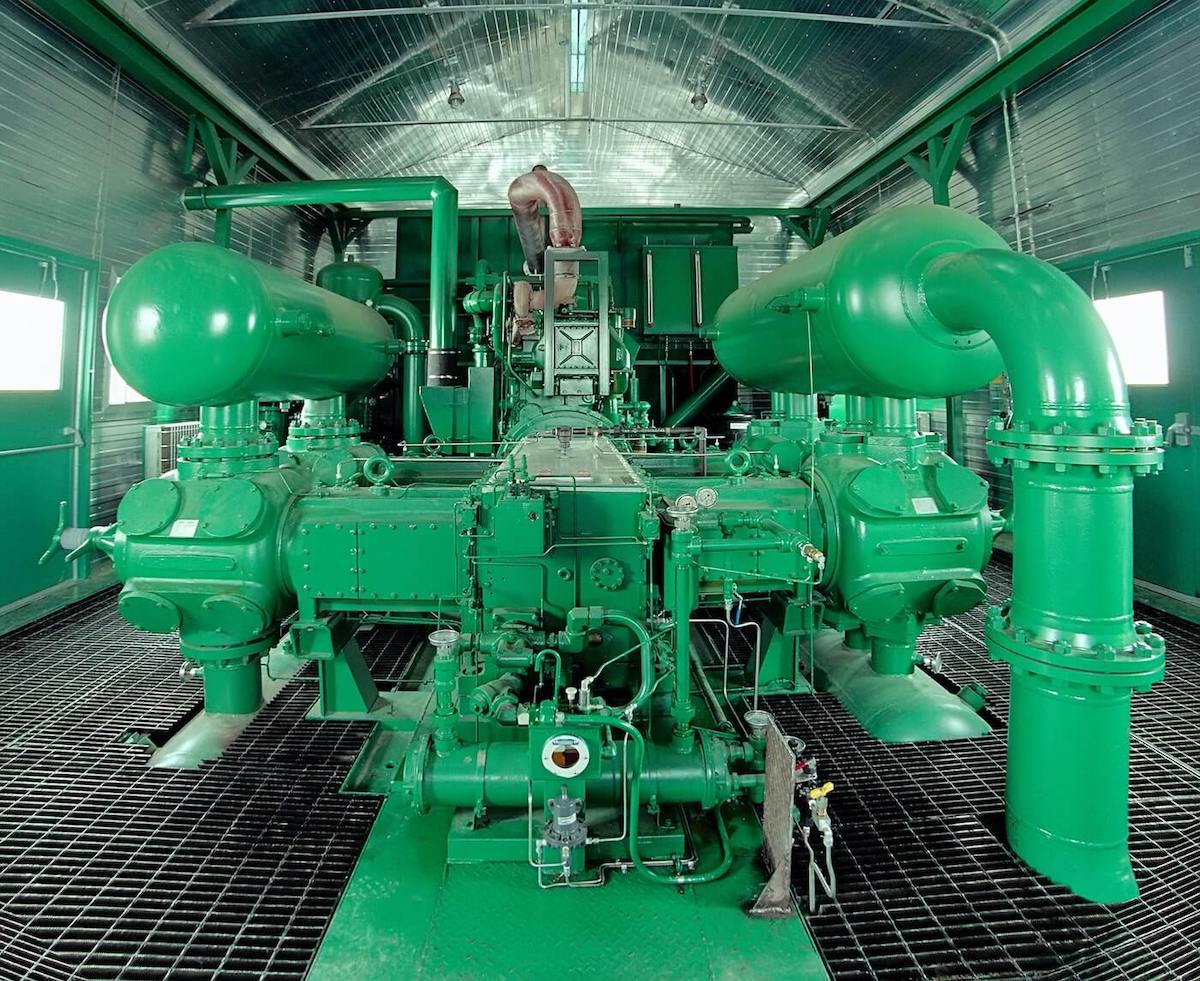

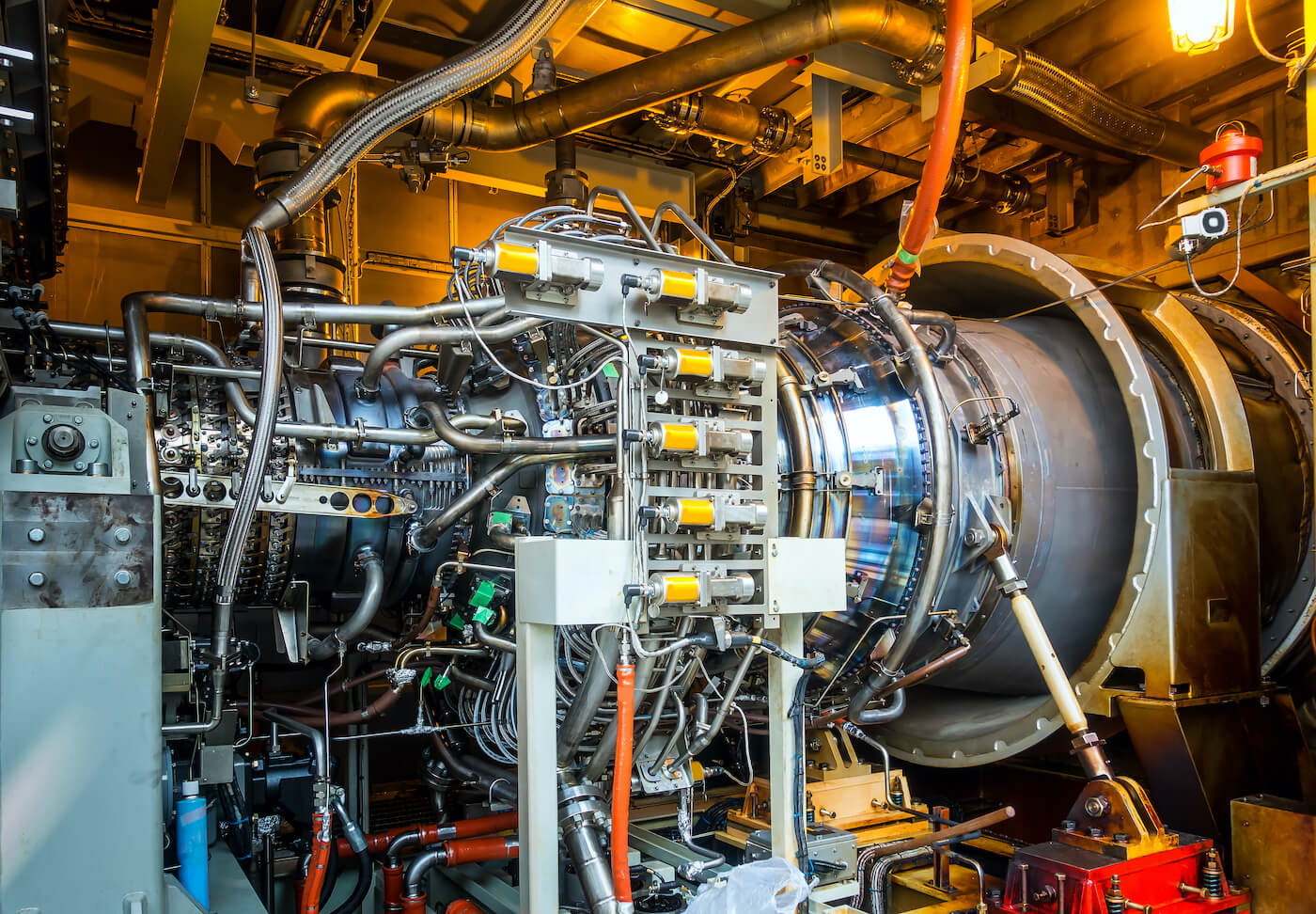

The most advanced ultraviolet flame detector on the market, Omniguard® model 660 is designed to function in the most challenging environments, with the capability to operate at extremely high temperatures (125°C) and a response time of 15 milliseconds. Typical applications for the Omniguard® 660 model are turbine enclosures, powerplants, compressor stations, LPG failities, LNG facilities, aand engine test cells.

OMNIGUARD MODEL 860 – UV/IR FLAME DETECTOR

By combining ultraviolet and infrared sensors with micro-circuit technology, the highest possible levels of sensitivity and reliability have been achieved. The model 860 detector utilises a highly sensitive, solar blind, ultraviolet sensor, along with its narrow band infrared (thermopile) sensor to ensure unbeatable performance. The model 860 is available in two versions, one for hydrocarbon fires only, and one for hydrocarbon and certain non-hydrocarbon fires. Typical applications for the Omniguard® 860 model are refineries, turbine enclosures, petrochemical plants, tank farms, powerplants, compressor stations, LPG facilities, LNG facilities, hangars and paint booths.

OMNIGUARD MODEL 760 – MULTI-SPECTRUM IR FLAME DETECTOR

Model 760 is the most advanced multi-spectrum IR5 flame detector in today’s market. In a breakthrough technological advance, the model 760 senses infrared radiation in five discreet infrared wavelengths. The multi-spectrum sensor information, combined with the sophisticated algorithm, enables the model 760 the ability to quickly detect hydrocarbon and certain non-hydrocarbon fuelled fires. The Model 760 also provides detection for hydrogen fires. Typical applications for the Omniguard® 760 model are refineries, pipelines, production platforms, power plants, compressor stations, LNG facilities, LPG facilities, tank farms, hangars, and petrochemical plants.

Accesories

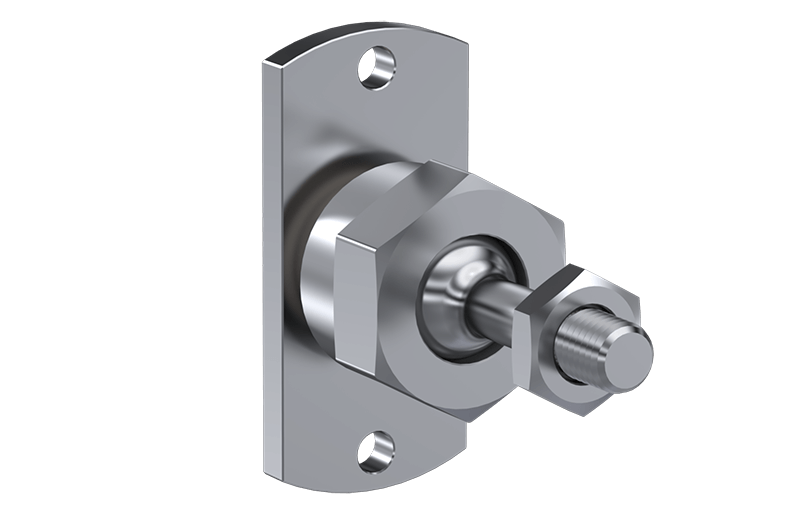

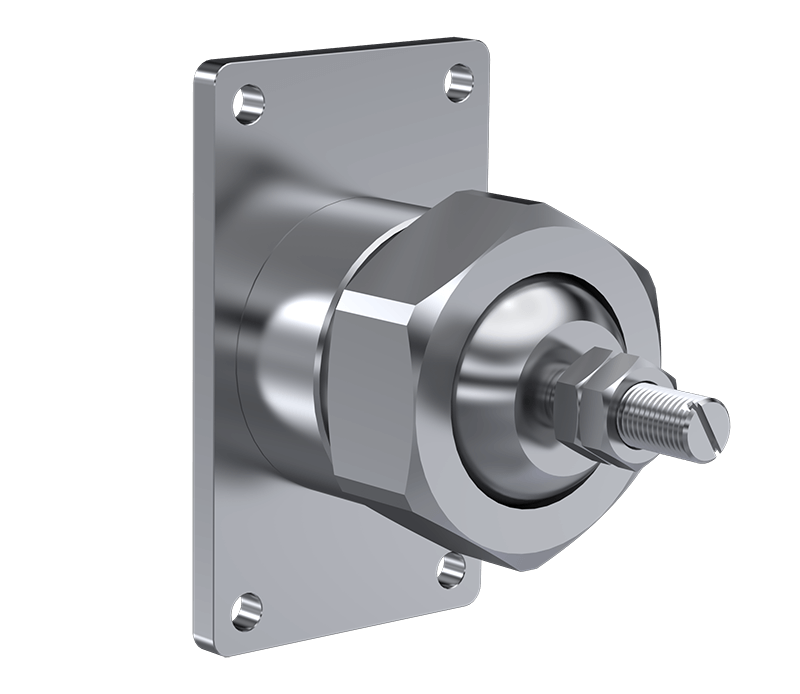

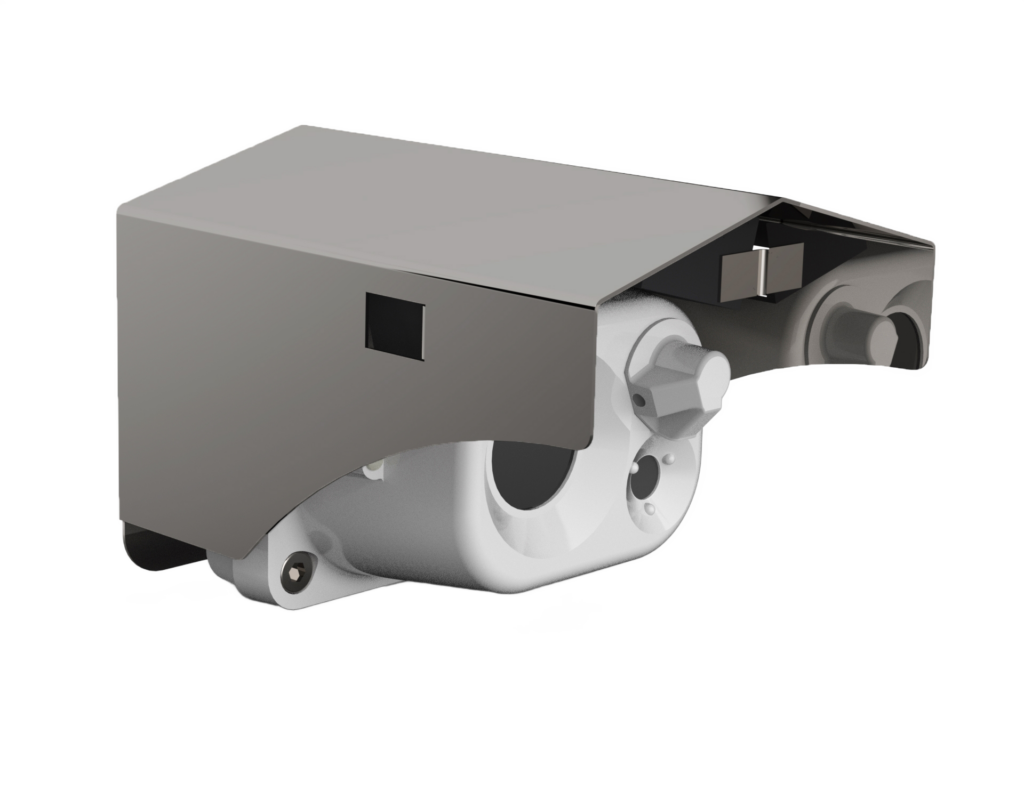

Swivel mount for all Aluminum 660/760/860 Flame detectors

Material: Stainless Steel 304

Part number: 20856

Swivel mount for all Stainless Steel 660/760/860 Flame detectors

Material: Stainless Steel 316

Part number: 24784

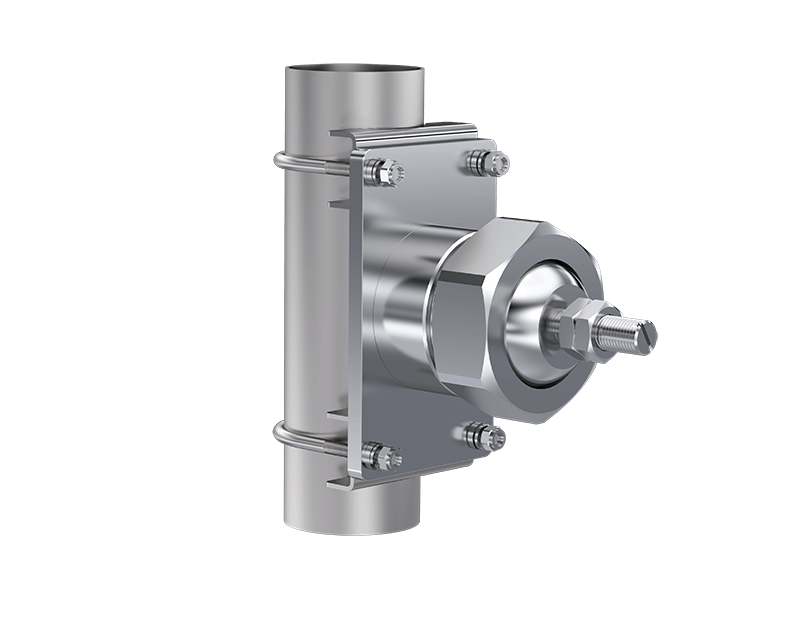

Pole mount 2″ for Swivel mount 20856

Material: Stainless Steel 316L

Part number: 26803

Pole mount 2″ for Swivel mount 24784

Material: Stainless Steel 316

Part number: 26807

Weather shield for all 660/860 Flame detectors

Material: Stainless Steel 316L

Part number: 23546

Weather shield for all 760 Flame detectors

Material: Stainless Steel 316L

Part number: 27976

Air shield for all 660/860 Flame detectors

Material: Delrin, Sintered Brass

Part number: 8001023

Air shield for all 660 High-temp Flame detectors

Material: Aluminum, Sintered Brass

Part number: 26489

Air shield for all 760 Flame detectors

Material: Delrin, Sintered Brass

Part number: 19797

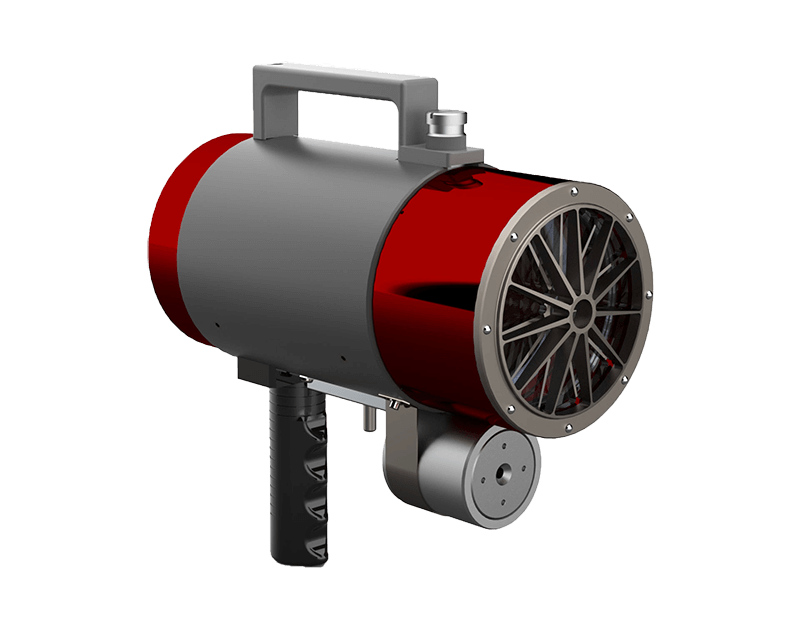

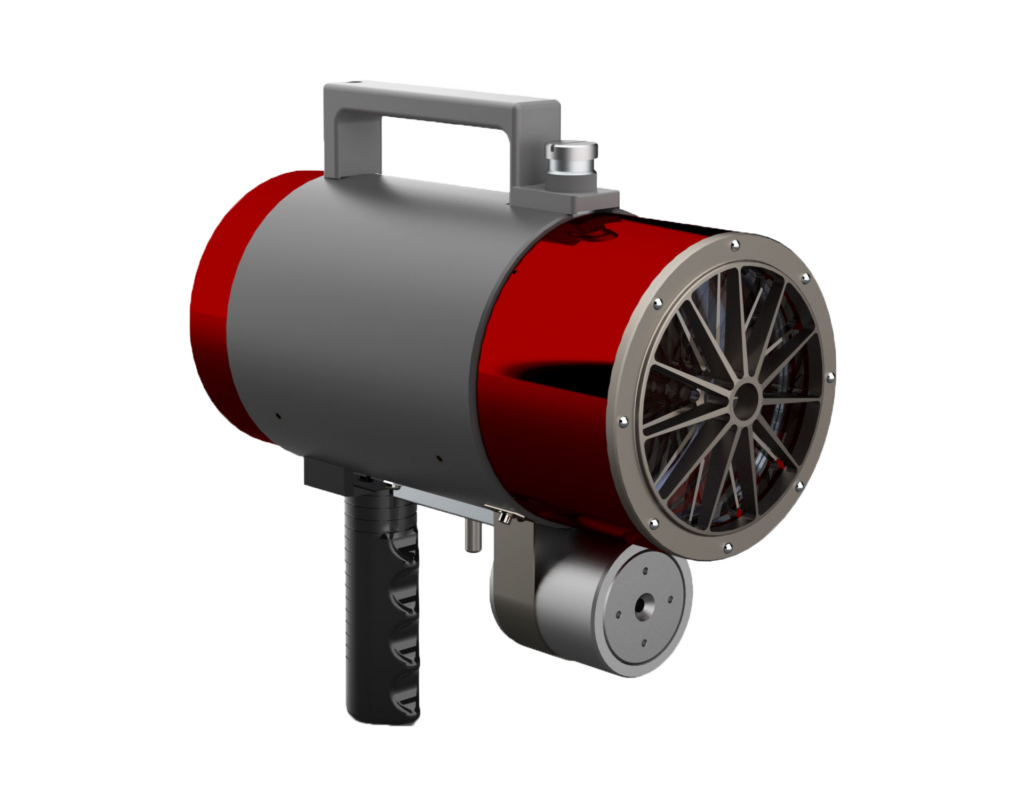

Test Gun for all 660 Flame detectors

115VAC, USA, Canada

Part number: 43808-2

Test Gun for all 660 Flame detectors

100-240VAC

Part number: 43808-3

Test Gun for all 660/860 Flame Detectors

Part number: 540

Test Gun for all 660/760/860 Flame Detectors

Part number: 545

Applications

-

AIRCRAFT HANGARS

-

BATTERY ROOMS

-

COMPRESSOR STATIONS

-

FUEL TRANSFER STATIONS

-

GAS STORAGE

-

HYDROGEN FACILITIES

-

LGP FACILITIES

-

LNG FACILITIES

-

MANUFACTURING INDUSTRY

-

MUNITIONS FACILITIES

-

PAINT BOOTHS

-

PETROCHEMICAL PLANTS

-

POWER PLANTS

-

PRODUCTION PLATFORM

-

PUMP STATIONS PIPELINE

-

REFINERIES

-

SILANE STORAGE

-

TANK FARMS

-

TURBINE ENCLOSURE

-

WASTEWATER